Not all ammunition is created equal. Especially when dealing with rimfire accuracy. I’ve heard this statement repeated over and over again throughout my life. The most advanced shooters can tell you what bullet, powder charge, primer, and even the brass that shoots the best in their rifles. So what makes ammunition Accurate?

Rimfire ammunition accuracy can be largely attributed to components and quality control. Making each individual round as consistent as possible. This is not easy to do in large-scale manufacturing, which normally leads to an increase in price. Many see this increase in price to be unfathomable and settle for the standard ammunition.

But what difference does that match ammo actually make? Does it justify the cost?

Affiliate Disclosure: This article may contain affiliate links. When you use these links, I earn a small commission from each sale generated at no cost to you. This commission helps me continue to put out free content. I work a full-time job that I am very happy with; therefore, I don’t need this commission and am not obligated to speak highly of any product. Everything written is my own opinion: the good, the bad, and the ugly.

This is a continuation article of The Pursuit of Rimfire Accuracy Part 1.

Ammunition Manufacturing

When chasing down the best possible accuracy with any rifle, it is important to use quality ammunition. For centerfire, this usually means picking each individual component, measuring the powder charge perfectly, and finding what your rifle likes. For rimfire, it’s a little different. Aside from some small rimfire reloading kits, factory ammunition is the only option.

This means that you must rely on factory ammunition for accuracy. This is a scary thought for us centerfire reloaders, who are used to getting a high level of accuracy when reloading our own ammunition. Much of the U.S. market is tooled toward pumping out as much ammunition as absolutely possible, as fast as absolutely possible. Generally speaking, this leads to ammunition that isn’t quite up to par with some of the foreign manufacturers.

When you see “Benchrest, Match, or Target” on a box of rimfire ammo, what should you expect? On the manufacturing end, you will see smaller quantities produced due to the higher attention to detail. In Rimfire Revolution by Michael R. Shea, he notes how some of the top-of-the-line European manufacturers operate in near-surgical conditions. Temperature and humidity-controlled rooms, handling the components with extreme care between each step.

This match ammo is made to deliver increased accuracy by providing tighter tolerances on bullet weight and powder charges. This, besides using higher-quality components, is a recipe for success. While standard ammunition works great for most shooters spending the weekend on the range, match ammo is best reserved for those trying to get the most accuracy out of their rimfire rifle.

The Rimfire Accuracy Test

This test is based on the ammunition component to accuracy. Accuracy is consistency, so I measured the consistency of the two ammunition brands tested. To do this, we ran a box of each ammunition through a chronograph and put it on paper. Accuracy largely depends on the rifle, so we will not include that data in this test. Instead, we look directly at the ammunition in relation to velocity.

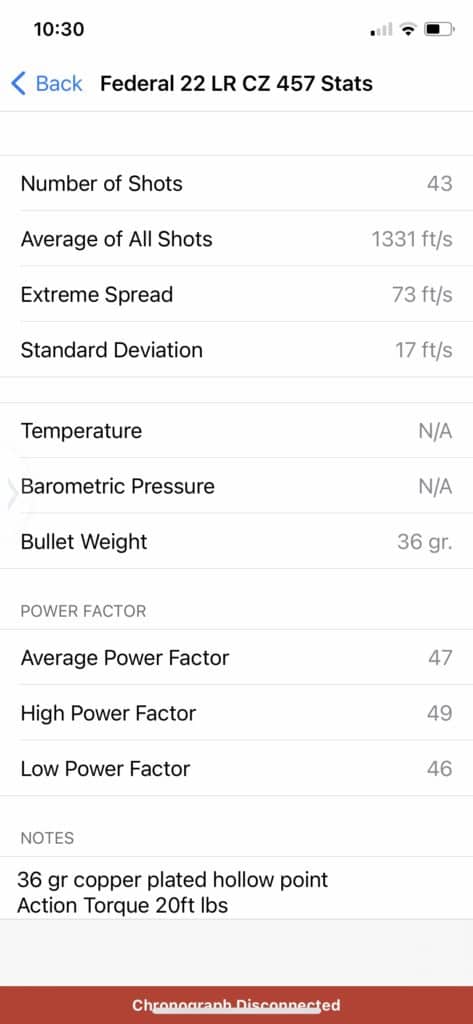

I had a box of ELEY 40 gr Match and Federal 36gr copper-plated hollow point ammo for the initial testing. I ran each through the Competition Electronics Pro Chronograph, collecting velocity data such as average velocity, minimum, maximum, extreme spread, and standard deviation. The digital link app that syncs up with the chronograph is great for this and does all of the work for you. The pictures below are some examples of how the chronograph organizes your data after completing your shot strings.

All of the shot velocities were recorded in an indoor range, so any weather conditions were not a factor. I monitored the barrel heat throughout the test to ensure that it had no effect on velocity.

The Results

- Average Velocity – Average velocity of each ammunition type.

- Minimum Velocity – Lowest recorded velocity with that particular box of ammunition.

- Maximum Velocity – Highest recorded velocity with that particular box of ammunition.

- Extreme Spread – Difference between the lowest and highest recorded velocity.

- Standard Deviation – Average dispersion of each brand of ammunition in relation to the average velocity.

| Federal 36 gr | Eley Match 40 gr | |

| Avg. Velocity | 1331 fps | 1088 fps |

| Min. Velocity | 1298 fps | 1068 fps |

| Max. Velocity | 1371 fps | 1112 fps |

| Extreme Spread | 73 fps | 44 fps |

| Std. Deviation | 17 fps | 10 fps |

Rimfire Accuracy: Applying the Data

As you can see from the above results, the match ammo showed more consistency than factory ammunition. Therefore is more accurate if shot out of a consistent platform. There are many ammunition options out there and I challenge you to find what is the most compatible with your gun. The big takeaway from this experiment was how much I learned by running every shot through a chronograph.

Use coupon code KTG10 to get 10% off your order of $150 or more at Brownells.

When grouping shots with the match ammo I’d have a group that could be covered up with a dime and then have one shot hit half an inch high at 50 yards. Looking at the chronograph I could see that that round was 20-25 fps faster than the others. The best groups were absolutely dictated by the spread of velocity. Finding the ammunition with the least amount of variation will lead to better accuracy.

This gives me a good baseline to go off of for further tests. I will be adding to this article as I get more varieties of ammunition run through the chronograph.

Written by: Kurt Martonik

Kurt is a Gunsmith, Reloader, Hunter, and Outdoorsman. He grew up in Elk County, Pennsylvania, where he became obsessed with the world of firearms. Following high school, Kurt enlisted in the United States Air Force as a Boom Operator, where he eventually rose to the position of Instructor. After his military service, he attended the Colorado School of Trades(CST) in Lakewood, CO for gunsmithing. Following graduation, he accepted a job at C. Sharps Arms in Montana, where he worked as a full time stockmaker and gunsmith.