There is very little information about the Winchester Model 43, commonly referred to as the Poor Man’s Model 70. It is a magazine-fed bolt-action rifle made by Winchester between 1948 and 1953. The Model 43 was chambered in 22 Hornet, 218 Bee, 25-20 Win, and 32-20 Win, making it a great option for the varmint hunter.

The Winchester Model 43 was not considered a commercial success. In the five years it was produced, just over 62,617 were produced. Essentially a larger and stronger version of the Winchester Model 69A, it never really caught on.

In this article, we will cover every aspect of the Model 43’s design. If you are looking for a general overview of the Model 43 and its variations, the first article I wrote might be what you’re looking for, The Winchester Model 43: Really the Poor Man’s Model 70?

Affiliate Disclosure: This article may contain affiliate links. When you use these links, I earn a small commission from each sale generated at no cost to you. This commission helps me continue to put out free content. I work a full-time job that I am very happy with; therefore, I don’t need this commission and am not obligated to speak highly of any product. Everything written is my own opinion: the good, the bad, and the ugly.

Digging Down Deep – Winchester Model 43 Action

The Winchester Model 43 action is not a very strong action. Frank De Haas, the author of Bolt Action Rifles, described it as a beefed-up Winchester Model 69A action. The action uses a single locking lug and the opposing bolt handle for its rear lock-up. The bolt body does not rotate, which makes it very smooth to operate. It is a Winchester speed lock design with a very fast lock time. The bolt throw is only about 60 degrees, allowing for a low-mounting scope without issue.

It is a controlled feed design, meaning that the cartridge slips up under the extractors during feeding and is under full control of the bolt throughout the entire process. This prevents double feeding from the magazine and ensures there will be no hiccups during operation.

The Receiver

The receiver is 6.300” long, and made from a piece of hardened tubular alloy steel with a diameter of 1.050”. The threaded shank of the barrel is 0.625” long, 0.805” major diameter, and 20 threads per inch with “V” type threads. The only markings on the receiver are the serial number and “WP Oval.” The serial number is located on the left side of the early models and the right side of the later “A-Series” Model 43s. The “WP Oval” is stamped on the top of the receiver ring.

A-Series rifles are covered in detail in my previous article.

All receivers were drilled and tapped for a Lyman No. 57A Rear Sight. These two holes will be located on the left rear of the receiver. Early Model 43s were not drilled and tapped for a scope. These receivers had a 45-degree bevel at the top rear of the ejection port. Around serial number 31,780, the receiver no longer had the 45-degree bevel and was factory-drilled and tapped. Despite the many variations found, Winchester only drilled and tapped the top of the receiver, two holes on the front receiver ring, and two holes directly behind the ejection port. Any other configuration, such as a side or barrel-mounted scope, is not original.

The Bolt Assembly

The Winchester Model 43 bolt assembly is a critical part of the smooth, controlled feed, cock-on open design. This assembly is made up of the following fourteen parts; Breech Bolt, Breech Bolt Sleeve, Breech Bolt Sleeve Pin, Breech Bolt Cocking Sleeve, Breech Bolt Plug, Extractor Right, Extractor Left, Extractor Pin(2), Extractor Spring Right, Extractor Spring Left, Firing Pin, Firing Pin Spring, and the Firing Pin Stop Pin.

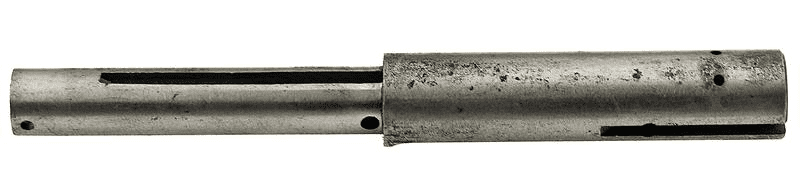

Breech Bolt

The main part of the bolt assembly is the breech bolt. It is a non-rotating bolt machined to hold both left and right extractors and has a recessed bolt face that fully supports the rimmed cartridges during firing. The bottom of the breech bolt is machined flat to prevent the chance of double feeding and allow the cartridges to be more in line with the bore before feeding.

The rear part of the breech bolt is a smaller diameter (0.494”) than the front (0.684”) and is made so that the bolt cocking sleeve and bolt sleeve can fit over it. The inside is machined to hold the firing pin and firing pin spring. The bottom of the breech bolt is serialized using an electric pencil and should match the receiver serial number. The 22 Hornet has a different breech bolt than the other cartridges due to having a different cartridge rim size.

Extractors

The Model 43 contains two extractors, a left and a right one. They are held in by two small pins and tensioned with individual small coil springs. The right extractor does most of the extraction work, while the left aids in ejection. A close examination of these two extractors shows that they differ slightly. The right extractor has a sharper hook that forms a 90-degree angle, while the left has a sloped angle to allow the cartridge rim to rotate out during ejection.

The extractors play an important role in the controlled feed of this design. Upon extraction, the extractors work together and essentially squeeze the cartridge holding it against the recessed bolt face until the ejector comes into contact with the cartridge rim. The cartridge then rotates out, exiting the ejection port. Both extractors are stamped with an “I.”

The two extractor springs differ from each other in length. The left extractor spring is shorter, measures approximately 0.220”, and has four full coils. The right extractor spring is approximately 0.300” long and has six full coils. Both springs have a “full-coiled” end that should face out when reassembled.

The extractor pins are the same for both left and right extractors. The pins are beveled on one end and should be driven out from the bottom and installed from the top of the breech bolt.

Breech Bolt Cocking Sleeve

The breech bolt cocking sleeve is one piece that includes the bolt handle, locking lug, bolt lock slot, and cocking cam. It is bored to a diameter of 0.497” to fit over the breech bolt. The bolt handle is a pear-shaped handle that, on early models, is a non-slanting design and is swept back towards the rear on later models.

The bolt handle works in conjunction with the locking lug to lock the action during firing. The bolt handle and locking lug are located opposite each other. There are two variations of the cocking sleeve. Beginning in 1950, a change was made to the locking lug that made it stronger. This was designated with the “A” suffix added to the serial number. At the same time, the serial number was moved to the left side of the receiver.

The breech bolt cocking sleeve also has a slot that allows the safety lever to engage it. A hook attached to the safety lever keeps the bolt locked closed when the safety is in the “safe” position. Lastly, the cocking cam creates the cock-on-open design while preventing the firing pin from striking the primer without being in full battery, an additional safety measure. Due to the design of the cocking cam and locking lugs, the bolt throw is about 60 degrees compared to the 90 degrees found on many bolt-action rifles like the Mauser 98.

Use coupon code KTG10 to get 10% off your order of $150 or more at Brownells.

Breech Bolt Sleeve & Breech Bolt Plug

The breech bolt sleeve serves as a spacer on the bolt assembly. It fills the gap between the Breech Bolt Cocking Sleeve and Breech Bolt Plug. It is pinned to the Breech Bolt and does not rotate during bolt operation. A small slot milled out at the bottom of the sleeve allows room for the firing pin when fully cocked.

The breech bolt plug’s only function is to hold the firing pin spring inside the breech bolt and create spring tension. It is pinned to the breech bolt and therefore does not rotate. It is slotted for a screwdriver in the rear and is commonly marred up by people trying to disassemble it improperly.

The Firing Pin & Firing Pin Spring

The firing pin is the main factor in the Model 43’s fast lock time. It weighs 0.49 oz and only travels 0.210” in during firing. The firing pin spring is positioned behind the firing pin giving it the force it needs to set off a primer. It is a protrusion-type firing pin that stops its travel on the breech bolt.

The top of the firing pin has a hump that helps keep it aligned during operation. The bottom of the firing pin has two humps that both serve important functions. The rearmost hump is an angled cocking cam and cocks the firing pin on the Breech Bolt Cocking Sleeve. The front hump is the sear engagement surface that rests on the trigger when cocked. A small channel is milled in the body of the firing pin that allows for the Firing Pin Stop Pin. This pin is what keeps the firing pin in the breech bolt.

The firing pin spring powers the firing pin during the firing sequence. It is positioned behind the firing pin and is held in by the Breech Bolt Plug and Breech Bolt Sleeve Pin. It is approximately 2.970” in length uncompressed and has 26 coils. The spring coil diameter is 0.053”, has an O.D. of 0.335” and I.D. of 0.230”.

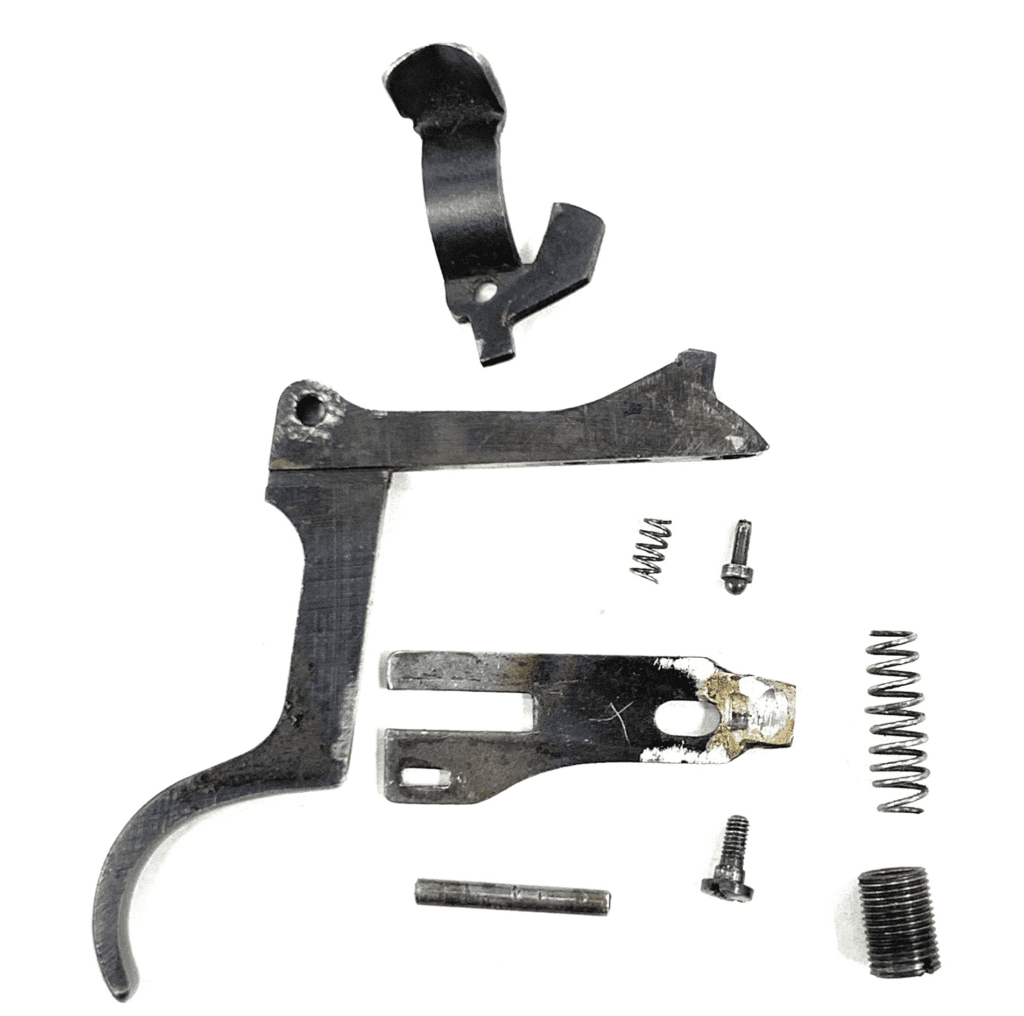

The Trigger Assembly

The trigger mechanism on a Model 43 is a very simple and straightforward one made up of ten parts: trigger, trigger base, trigger pin, trigger spring, trigger spring adjustment screw, safety lever, safety lock, safety lock screw, safety lock plunger, and safety lock spring.

The trigger is a one-piece design that is a direct-acting type. The sear is not a separate piece in this design but part of the trigger itself. The trigger gets tension from the trigger spring that is inserted through the magazine holder. A hollowed-out plug screw is used to adjust the tension of the spring.

The trigger is of steel construction and is drilled and tapped for the safety lock screw and has a hole drilled for the safety lock plunger and safety lock plunger spring.

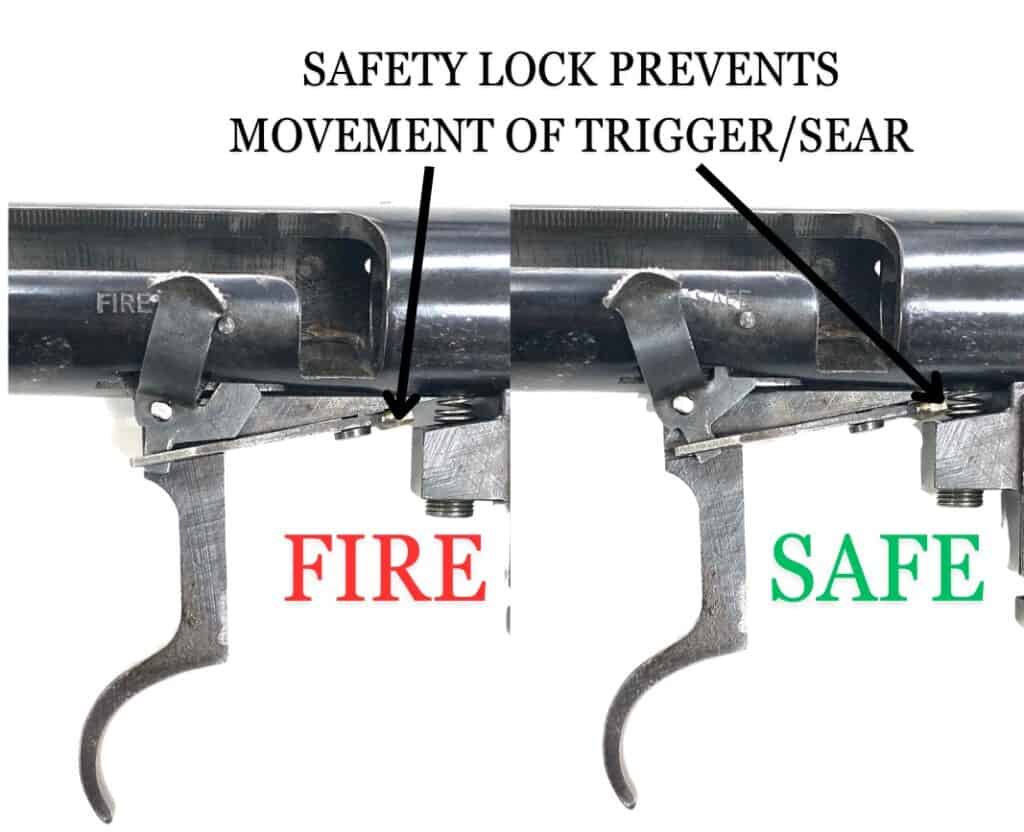

The Safety Mechanism

The safety mechanism is a simple one that blocks movement of the trigger/sear. It is a two-position safety and operates like most American rifles, forward=fire, back=safe. When in the rear position, or “safe,” it locks the bolt in the closed position. Therefore, one must take the rifle off safe to open the bolt and unload the rifle.

The safety lever has a finger on the bottom of it that rides inside the safety lock. Working as a lever, when the safety lever is pulled to the rear in the safe position, it slides the safety lock forward, wedging itself between the trigger and magazine housing, preventing the trigger movement. When the safety lever is moved forward, the safety lock slides to the rear and allows the trigger to be operated freely.

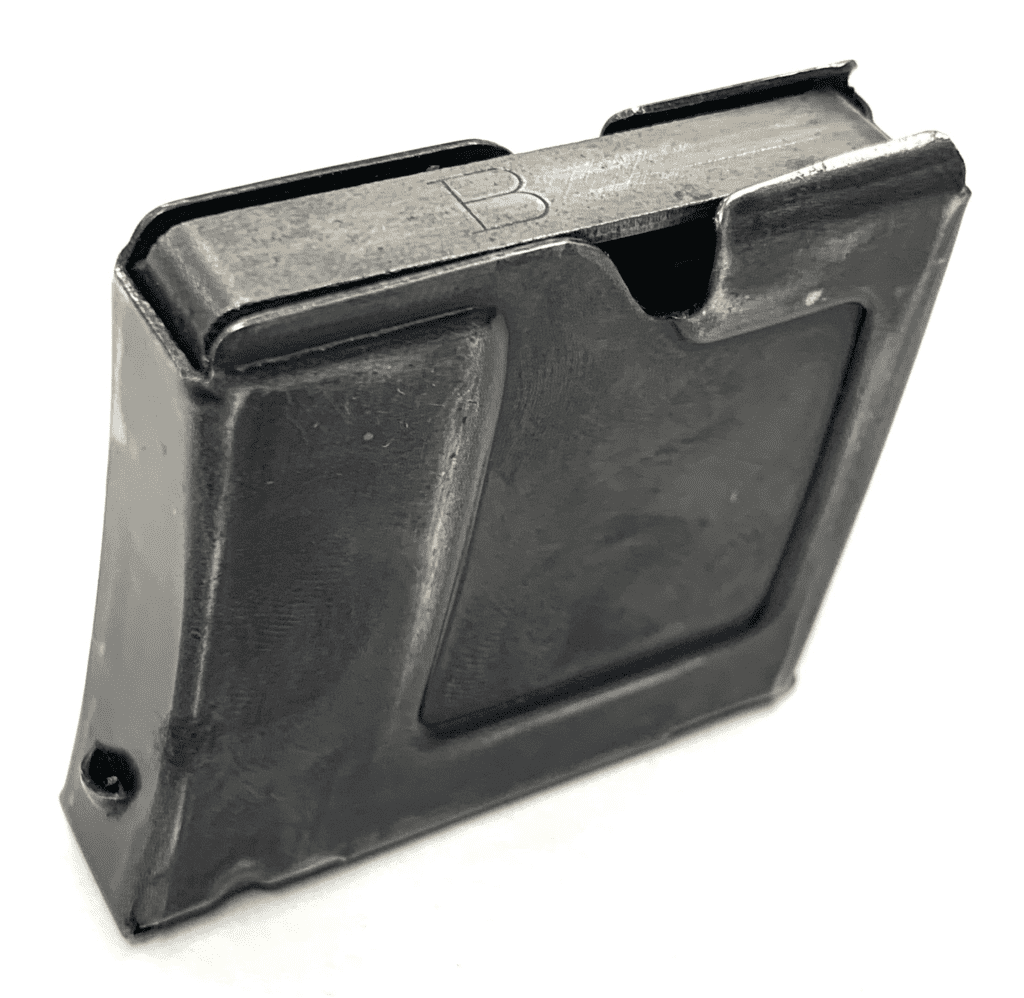

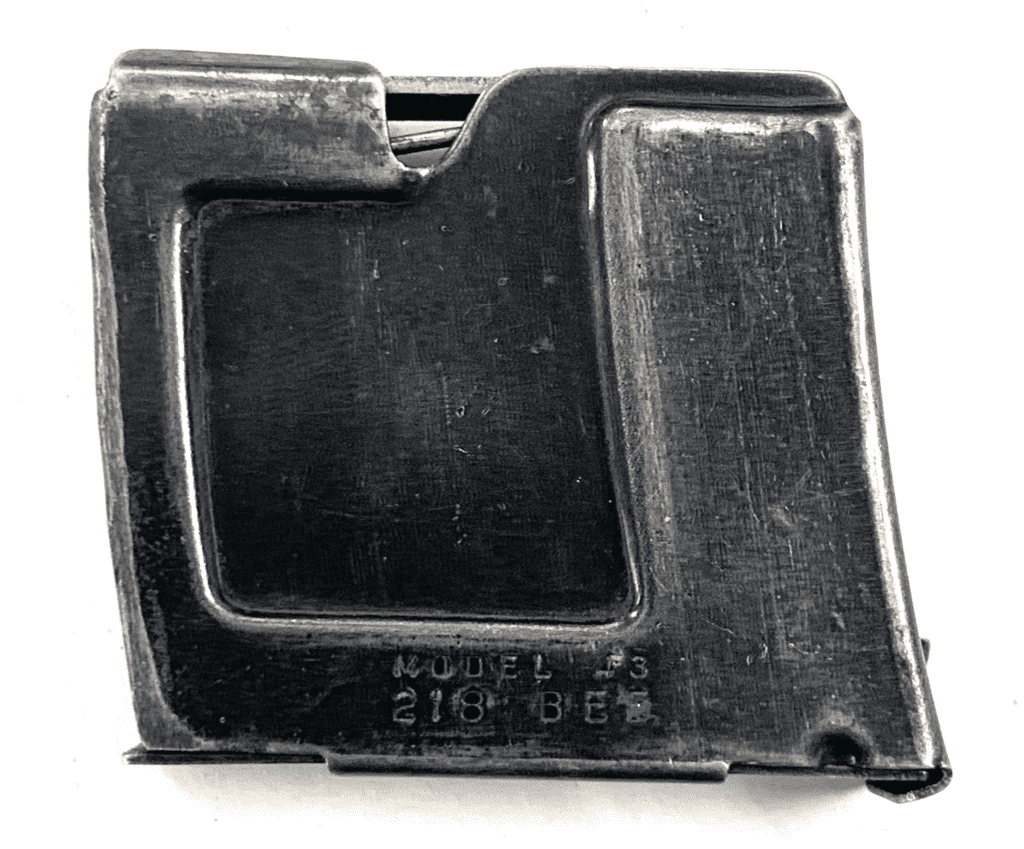

The Winchester Model 43 Magazine

The magazine is a detachable box that fits flush with the bottom of the stock. There are two types of these magazines. One works with the .218 Bee, 25-20, and 32-20, and the other is 22 Hornet specific. The magazine is made up of four parts; magazine body, magazine spring, follower, and floor plate.

The magazine body is a stamped piece of steel that has a slight curve to it. The back of the magazine has a hole drilled in it for the magazine catch. The front of the magazine body has a small nub that rests against the magazine holder when fully seated, keeping the magazine aligned correctly. The 22 Hornet magazine has a milled-out “U” in the front of it, which I believe was done to allow longer bullets to feed properly.

218 Bee Magazines are marked with a “B” on the follower. Original magazines were stamped on the right side of the magazine body, “Model 43” above the caliber. Aftermarket 4 & 5-round magazines are available and protrude from the bottom of the stock.

The Barrel

The Winchester Model 43 had a 24-inch tapered round barrel made of “Winchester Proof Steel.” Chambered in the .218 Bee, .22 Hornet, .25-20, and .32-20, the exterior profile was the same across the board. The straight tapered barrel measures 0.875 inches at the receiver ring and 0.567 inches at the muzzle. The 22 Hornet and 218 Bee had a 1:16-inch twist rate.

The front sight ramp is machined into the barrel and stippled to provide a surface that reduces glare. The barrel was dovetailed in three places; the rear sight, the front sight ramp, and the stock stud on the bottom of the barrel. The stock stud is the recoil-bearing surface for the Model 43. Again, the barrel on Winchester Model 43s was never drilled and tapped for a scope at the factory.

The barrel was stamped with the classic roll mark that bears most Winchester barrels of the era. A Winchester proof mark is also found at the 12 o’clock position near the receiver. At the 6 o’clock position, the timing witness mark and the year the barrel was manufactured are stamped. The caliber is again found on the bottom of the barrel.

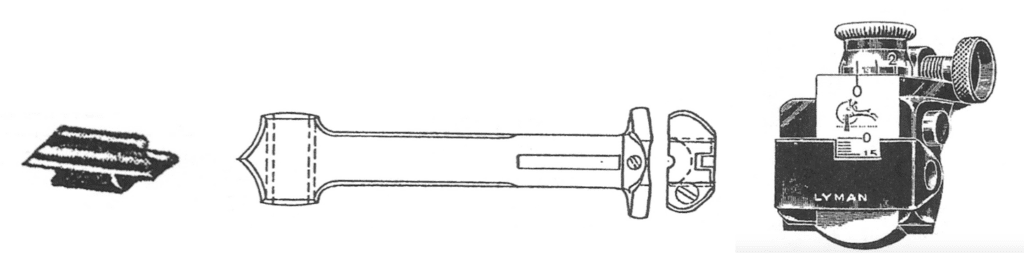

Sights

As mentioned previously, the front sight base was machined into the barrel and dovetailed to accept a Winchester 103 Bead Front Side with a removable sight cover. The rear sight was a Winchester 22K sight, with their “Rocky Mountain flat top” sight picture. Lastly, the receiver was drilled and tapped at the factory for the Lyman 57 receiver sight. This hole spacing also accommodated the more affordable Williams 5D-34.

Wrapping It All Up

The Winchester Model 43 doesn’t get the fame it deserves, in my opinion. They are great little rifles chambered in fun cartridges. While they were known as the “Poor Man’s Model 70,” in many cases, they command the same price as their bigger brothers. Do you have experience with the Winchester Model 43? Let me know in the comments!

Written by: Kurt Martonik

Kurt is a Gunsmith, Reloader, Hunter, and Outdoorsman. He grew up in Elk County, Pennsylvania, where he became obsessed with the world of firearms. Following high school, Kurt enlisted in the United States Air Force as a Boom Operator, where he eventually rose to the position of Instructor. After his military service, he attended the Colorado School of Trades(CST) in Lakewood, CO for gunsmithing. Following graduation, he accepted a job at C. Sharps Arms in Montana, where he worked as a full time stockmaker and gunsmith.

I have a model 43 in 218BEE, fun rifle to shoot,made in 1950,bought it for $250.00

Just like shooting vintage rifles,and reloading for them

I have a Model 43 in 218 Bee. Definitely a fun rifle to shoot. My grandfather also owned a Model 43 in 218 Bee and harvested everything from varmints to deer with it.

I have model 43 in .22 Hornet that belonged to my grand father but the barrel is not good is rusted on the inside do you know where I can find a new barrel or some body that can make a new one or repair the same one

I have a Winchester model 43 (1951) .22 Hornet. Does anyone know where I can find an original sight cover.

Thanks in advance

Check eBay and Numrich arms!