In Part Three of my Pursuit for .22 Accuracy, we’re going to take a look at action screw torque. This is a very important aspect of accuracy in a rifle, and this test proves that. While all of these tests are being done using a CZ 457 rifle chambered in .22 LR, this concept applies across the board for rifles of all calibers.

The goal is to see if there is a noticeable difference in group size between different torque settings. If there is a difference, how much. This test was inspired by Micheal R. Shea’s book Rimfire Revolution, which I reviewed here.

Affiliate Disclosure: This article may contain affiliate links. When you use these links, I earn a small commission from each sale generated at no cost to you. This commission helps me continue to put out free content. I work a full-time job that I am very happy with; therefore, I don’t need this commission and am not obligated to speak highly of any product. Everything written is my own opinion: the good, the bad, and the ugly.

Equipment

Rifle – CZ 457 American chambered in .22 LR

Scope – Leupold VX-3i 3.5-10x40mm

Scope Mounts – Warne

Torque Wrench – Wheeler Engineering Fat Wrench

Chronograph – Competition Electronics Pro Chrono DLX

The Conditions

To properly test this theory, I wanted to eliminate as many variables as possible. This meant using the same type of ammo and shooting in controlled conditions. I am lucky to have access to a 50 yd private indoor range to do the testing. Wind, temperature shifts, and scope glare due to lighting are eliminated.

For ammunition, I used the ELEY Match 40 gr flat point. Every shot passed through the chronograph to make sure the ammo was consistent shot to shot. Throughout this test, our extreme spread was 44 ft/s and had a standard deviation of 10 ft/s. The average velocity was 1088 ft/s.

Rifle Cleaning. Here is where some debate may ensue. I started the test with a rifle that had a box of ammunition through it and did not clean the rifle throughout the entire test. Since this is my small game hunting rifle it would not be cleaned before every outing. Therefore, I mimicked how the actual rifle would be used in the field.

The Torque Setting Criteria

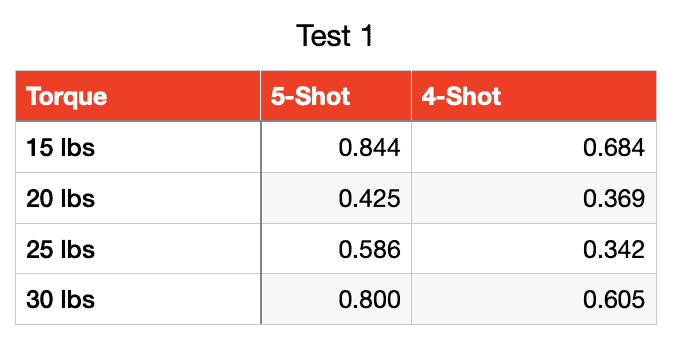

For this test, I shot ten five-shot groups. I started with the action screws torqued to 15 inch-pounds and worked up to 30 in-lbs in 5 lbs increments. For each adjustment, I would tighten the forward action screw first, then the rear. Once I worked through the four different screw torque settings, I further narrowed it down between the most accurate settings and went in 2.5 lb increments.

For group size, I measured center to center of the two with the most spread. I did this for 4 and 5-shot groups to account for any fliers or inconsistencies, both numbers will be posted.

The Test Results: Action Screw Torque Matters

Test 1 showed some obvious data points. First, at 15 lbs of torque, accuracy was a little sporadic. Second, 20 and 25 lbs had the best groups by far with 20 lbs being the most accurate. Test 2 would cover the range of between 20-25lbs.

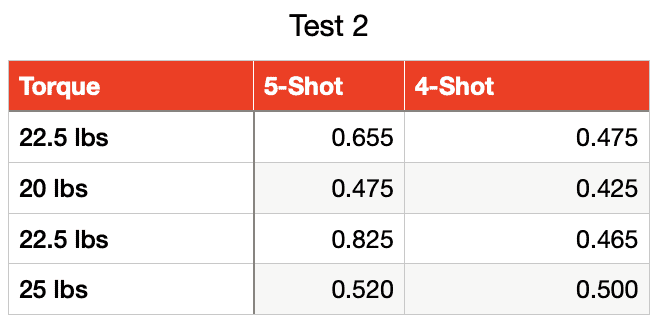

Test 2 started with 22.5 Inch-pounds of torque. The grouping was bigger than expected. To reconfirm the previous groups I decided to shoot 20, 22.5, and 25 again. The new data showed that 20 lbs of torque was the sweet spot.

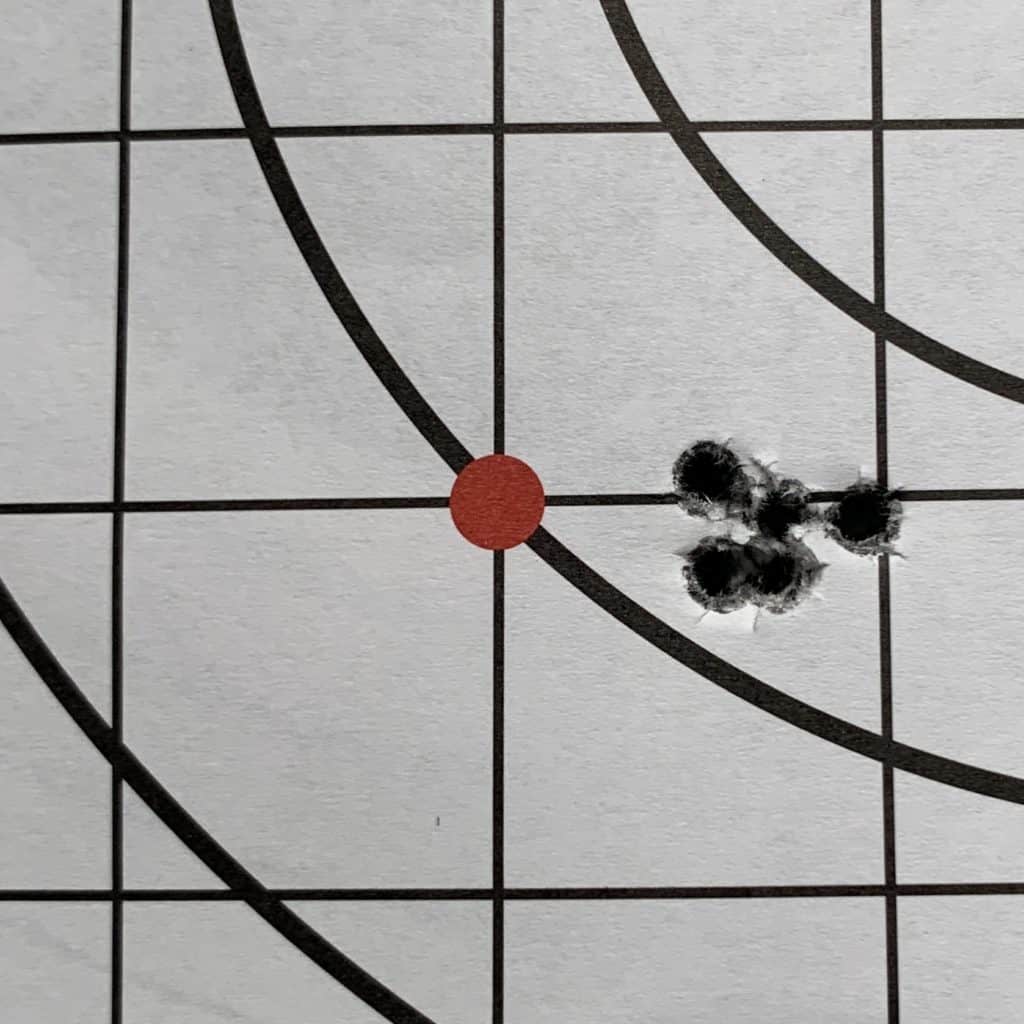

Reconfirmation of the test results involved me removing the action screws entirely from the gun and retorquing them to 20 lbs. This final group ended up being the best of the day, confirming my data.

These tests are specific to my rifle. You will more than likely see different results in your personal rifle, but this gives you a good test outline to go by.

Use coupon code KTG10 to get 10% off your order of $150 or more at Brownells.

Application

First and foremost, we did prove that action screw tension has an effect on accuracy. The other interesting thing that I noticed with this test was the Point of Impact(POI) change with each setting. At some torque settings, the POI would move close to an inch.

To maintain accuracy in your rifle, action screw torque needs to be taken seriously. After detail cleaning, the rifle should be torqued to the setting that you found most accurate in your own testing. Lastly, it is my opinion that this is the most cost-effective way to see an improvement in the accuracy of your rifles at home.

Written by: Kurt Martonik

Kurt is a Gunsmith, Reloader, Hunter, and Outdoorsman. He grew up in Elk County, Pennsylvania, where he became obsessed with the world of firearms. Following high school, Kurt enlisted in the United States Air Force as a Boom Operator, where he eventually rose to the position of Instructor. After his military service, he attended the Colorado School of Trades(CST) in Lakewood, CO for gunsmithing. Following graduation, he accepted a job at C. Sharps Arms in Montana, where he worked as a full time stockmaker and gunsmith.