I’m admittedly a little late to the BRN-180 game. I’ve always wanted one, but every time I had the cash to get one, something else would come across my bench that I couldn’t live without. I wish I hadn’t waited this long, as this design is pretty cool.

The BRN-180 is a short-stroke gas piston design based on Eugene Stoner’s AR-180. It comes in various caliber and barrel length options and shares some parts compatibility with the AR-15. The BRN-180 upper receiver will work on any Mil-Spec AR-15 lower receiver adding to its versatility.

This article is my attempt to answer the questions that I had to dig deep into when I was looking at purchasing one.

Affiliate Disclosure: This article may contain affiliate links. When you use these links, I earn a small commission from each sale generated at no cost to you. This commission helps me continue to put out free content. I work a full-time job that I am very happy with; therefore, I don’t need this commission and am not obligated to speak highly of any product. Everything written is my own opinion: the good, the bad, and the ugly.

It Is Not an Entirely New Design

Designed in conjunction with Primary Weapon Systems(PWS) and Foxtrot Mike(FM) Products, the Brownells BRN-180 is a short-stroke gas piston design based around Eugene Stoner’s AR-180. Eugene Stoner was the brainchild behind the AR-15 and saw the AR-180 as an improvement over the original design. The AR-180 was brought to the civilian market by Armalite in 1969, and over its 16-year production, only 21,478 were manufactured.

Many believe the AR-180 was ahead of its time, but it wasn’t a huge success when initially introduced. The BRN-180 short-stroke gas piston design was an improved version of David “Carbine” Williams’ design, used on the M1 Carbine. The original AR-180 was available in the 5.56×45 NATO cartridge only.

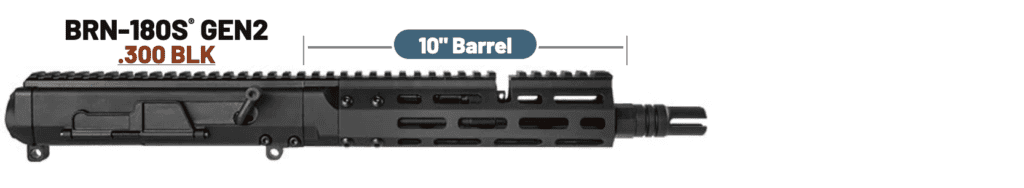

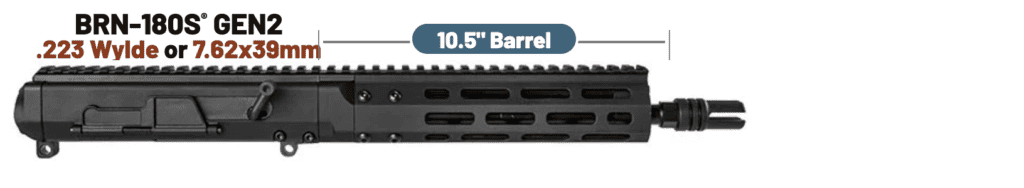

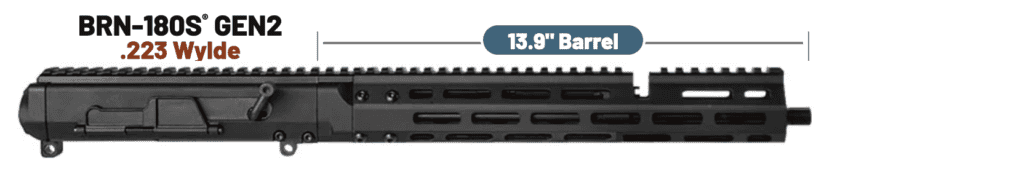

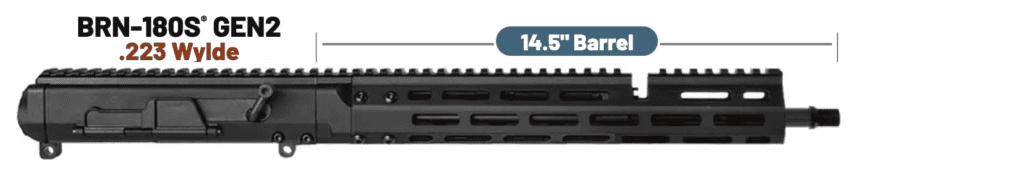

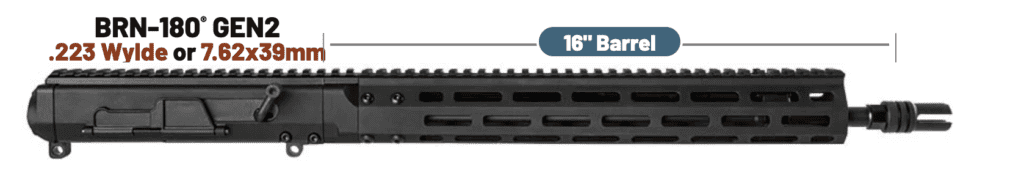

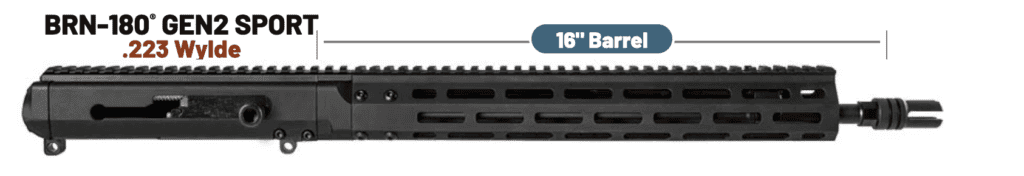

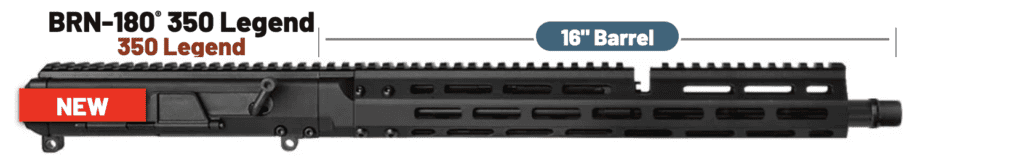

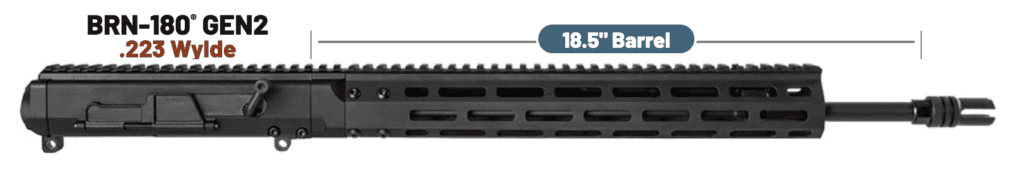

The BRN-180 was built to be a modern iteration of the AR-180, incorporating many of the design changes that adapt it to the modern market. Available in multiple barrel lengths and chambered in the 5.56 NATO, 300 BLK, 350 Legend, and 7.62x39mm, the BRN-180 is a very capable platform.

The biggest departure from the original AR-180 is the receiver design. Brownells designed it to work with any AR-15 lower receiver group, meaning that all of the lower receiver parts and components, as well as the receiver itself, are compatible with the AR-15. All of the components that make the BRN-180 bolt function are self-contained in the upper receiver. This allows the user to shoot the firearm without a stock or, better yet, with a stock in the folded position.

What Makes the BRN-180 Unique: The Gas System

Part of the reason the BRN-180 has been so successful so far is its use of a gas piston design. The direct impingement system used on the AR-15 has been highly criticized since its introduction, as it blows the cartridge’s hot and dirty gases directly into the receiver with each shot. A gas piston design keeps those hot gases out of the action.

Made by PWS, well-known for manufacturing gas piston designs for the AR-15, the gas system uses a short-stroke design. This means that the piston itself does not travel the entire distance that the bolt does. Instead, it stops short, and momentum carries the bolt to its rearmost travel, at which point the dual recoil springs return it to battery.

| Gas System Setting | Use |

| “1” | Unsuppressed/Suppressed Subsonic |

| “2” | Suppressed Super Sonic |

| “X” | Shutoff/Manual Operation |

The BRN-180 Gen 2 gas system is adjustable and, depending on which model you are using, will have two or three positions. The positions are labeled with a “1” and “2”, on two-position gas systems and an “X” for the third position found on the BRN-180SH. Position “1” is for use unsupressed and a suppressor with subsonic ammo, position “2” is with a suppressor and supersonic ammo, and the “X” position is the shutoff position only found on BRN-180SH models. The positions can be viewed through a milled-out slot on the top rail located near the gas block.

By adjusting the gas block, the user is changing the size of the gas port, allowing more or less gas into the system. Find what setting will work most reliably for your ammunition type. Overgassing the gun can cause premature wear.

Gas system Disassembly

The disassembly of the gas system is easy and can be done by removing the bolt assembly and accessory rail. Next, pull rearward on the piston assembly and lift it clear of the gas block. The video above shows this process pretty clearly. However, there is one caveat.

On 300 BLK upper receivers, users were experiencing premature wear on the piston springs. To counter this, PWS changed the piston op rod design. With this new design, the gas system can’t be disassembled without punching out the roll pin in the gas block and moving it forward 1/4″. While this is unfortunate, they have stated that now the springs are lasting exponentially longer.

Use coupon code KTG10 to get 10% off your order of $150 or more at Brownells.

The Barrel

The barrel of the BRN-180 is made of 4150 carbon steel and coated with a wear-resistant nitride coating. It is button-rifled and comes with a 1:8-inch twist rate for all three calibers available. The muzzle thread varies with each caliber. See the chart below as it outlines this more clearly.

| Caliber | Barrel Lengths | Twist Rate | Muzzle Thread |

| 223 Wylde | 10.5″, 13.9″, 14.5″, 16″, 18.5″ | 1:8″ | 1/2-28 TPI |

| 300 AAC Blackout | 10″ | 1:8″ | 1/2-28 & 5/8-24 TPI |

| 7.62x39mm | 10.5″, 16″ | 1:8″ | 5/8×24 TPI |

| 350 Legend | 16″ | 1:16″ | 1/2-28 TPI |

While the 300 AAC Blackout is advertised on their website as having a 5/8-24 TPI thread, mine was threaded to 1/2-28 TPI and came with a thread adapter installed for 5/8-24. After contacting PWS, they said that was now standard. However, I am unsure if the same configuration is found on the 7.62x39mm.

Related Article: Timing a Muzzle Device: The Quickest and Easiest Way

The BRN-180’s barrel is threaded onto a barrel extension similar to but not the same as the AR-15. This barrel extension houses the locking lugs and provides a place for the receiver to mate to the barrel. The barrel of the BRN-180 is pressed in and should not be removed. At the time of this writing, there are no aftermarket barrel options for the BRN-180.

The Bolt System

The bolt system on the BRN-180 is unique to the design and is completely self-contained in the upper receiver, eliminating the need for a buffer tube assembly. The bolt housing contains the bolt, bolt return spring, firing pin, cam pin, firing pin retaining pin, and charging handle. Disassembly is very similar to that of the AR-15 and easily done without tools.

The bolt itself has seven recoil lugs that bear against the barrel extension when in battery and is milled out to fit the standard M-16/AR-15 extractor. It is rotated into battery using the cam pin and utilizes a bolt return spring to ensure the bolt remains in the unlocked position when needed.

The bolt housing rides on internal rails that are machined into the upper receiver and employ dual guide rods and recoil springs. This setup makes for a very soft recoiling rifle that is smooth to operate. The guide rods are held in place by a polymer recoil block that absorbs the shock of the rearward travel of the bolt body.

Lastly, since the BRN-180 uses dual recoil springs that are contained within the upper, the AR-15 buffer tube, buffer spring, buffer, buffer retainer, and buffer retainer spring are not needed. Although not needed, they don’t have to be removed from the lower either. It can be fired with all of the parts in place without issue.

The Differences Between the BRN-180 Gen 1 and Gen 2

There are two main variations to the BRN-180, which are identified as Gen 1 and Gen 2. Gen 2s are an improved version of the Gen 1 and have some additional features that some find more desirable. Most notable are the handguard and adjustable gas block.

The Handguard

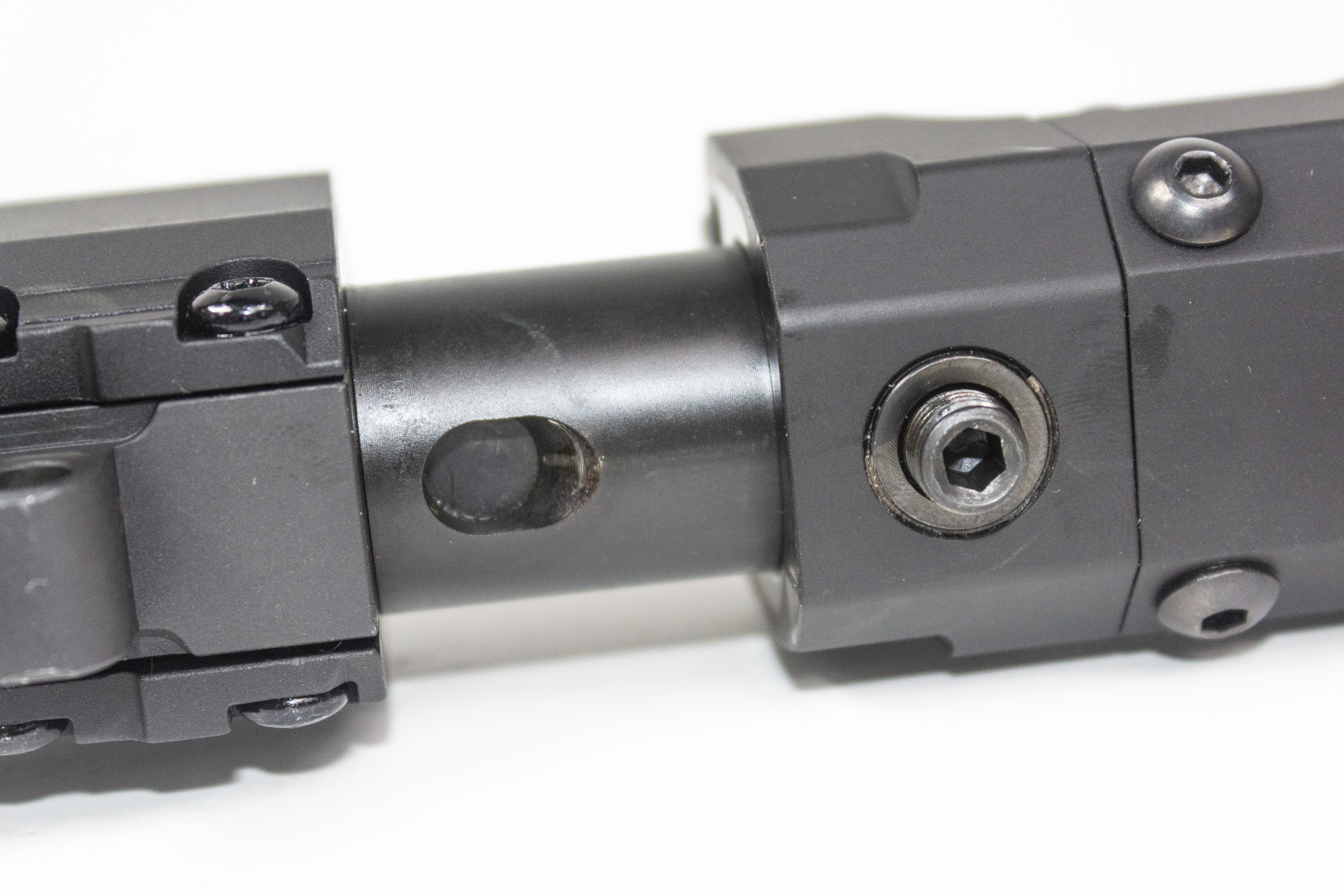

The M-LOK handguard that is included with BRN-180s was overhauled to have a more streamlined attachment mechanism. This new design uses a 5/32 hex wrench set screw that tightens against an angled surface on the barrel, pulling the handguard up tight against the upper receiver.

Adjustable Gas Block

Previously only found on the BRN-180S series of uppers, the Gen 2 BRN-180s now all come with a two-position adjustable gas system. With the exception being the three-position one found on the BRN-180SH model.

BRN-180 Parts Compatibility with the AR-15

One of the first questions I had when the BRN-180 was introduced involved parts compatibility. Primarily, does it have any compatibility with AR-15 parts? I am already set up for the AR-15 platform and have the spare parts necessary to keep it running for many years to come. Adding another rifle platform had me concerned about getting the necessary parts. Fortunately, I was happy when I saw that some parts were, in fact, compatible.

First and foremost, the BRN-180 upper receiver is 100% compatible with Mil-Spec AR-15 lower receivers. This means that BRN-180 upper receiver groups will work perfectly on any AR-15 lower receiver assembly. This was a great move on Brownell’s part, as there is already a seemingly limitless supply of aftermarket lower parts available for the AR-15.

Since the BRN-180 uses an AR-15 lower receiver, it uses the standard AR-15 magazines as well. A huge plus to those of us who already have a decent supply saved up. This will obviously be dependent on what caliber you choose, specifically the 7.62×39.

The firing pin, extractor, and ejector of the BRN-180 are also compatible with the AR-15. This is a great feature as those parts tend to be common wear areas with all semi-automatic firearms. If in doubt, give PWS a call on the specifics.

Replacement Part Availability

Brownells has done a great job ensuring that replacements for high-wear parts are available to purchase. For those parts that aren’t available at Brownells.com, contact PWS as their customer service has been excellent with any questions or help I’ve needed with the upper.

The Brownells BRN-180 Lower Receiver

Brownells also has a BRN-180 lower receiver that fits the upper perfectly and has a Picatinny 1913 rail in place of the buffer tube threads found on most AR-15 lowers. This allows for the attachment of different folding stock configurations, adding to its versatility.

Made out of 7075 Aluminum forgings, it differs from the original AR-18/AR-180 receiver that was made of stamped steel. However, the team at Brownells did a great job making the receiver look the part, as it has many cosmetic features to match the originals.

The BRN-180 lowers also differ from the originals in that it takes Mil-Spec AR-15 lower parts and feeds from standard AR-15 magazines. I touched on it briefly before, but having parts interchangeability is a major strong point of this design. The only issue I found with the lower is that any pistol grip with a beaver tail won’t work properly as the angle behind the grip is sharper. It looks like this isn’t an issue with the BRN-180M receiver.

The rear takedown pin’s spring configuration is slightly different than an AR-15 in that it is inserted from the bottom and held in place by the pistol grip. The bolt release is held in place by a roll pin and is not threaded like some of the newer designs.

Lastly, the fit on this lower receiver isn’t the greatest. There is a lot of play between the upper and lower when put together. It hasn’t bothered me too much yet, but it is something to be aware of.

The BRN-180SH

The newest addition to the BRN-180 lineup is the BRN-180SH. This is a 300 BLK upper that is optimized for use with a suppressor, including the ultra-quiet gas shutoff position. This is the first BRN-180 upper to offer the third position for the gas system, which makes it a very capable suppressor candidate. In the shutoff position, the firearm is operated like a straight pull bolt action, eliminating the excess noise caused by the operation of the action itself.

Along with the new gas shutoff position, the BRN-180SH also utilizes a new adjustable charging handle that can be positioned for the comfort of the user. It is a lower profile than the dog leg one found on the standard BRN-180 and gives the upper fewer things to snag on with pulling it out of a backpack or case.

The last major change that the BRN-180SH has is the lack of a dust cover. This change confuses me as many people already complain that the opening in the BRN-180 is already large and attracts dirt and debris. If I had to guess, the dust cover was eliminated to aid in the straight pull operation of the bolt.

Save 10% on any BRN-180 upper using code KTG10

In my opinion, the BRN-180SH is a great addition to the BRN-180 lineup. It filled a niche that many users were requesting. Having shot this through a suppressor, I can attest to how much quieter it is in the shutoff position.

Final Thoughts on the BRN-180

Overall I believe the BRN-180 is a great addition to anyone’s safe. It is the perfect balance of modern yet has a vintage vibe to it that made it an instant classic. We are just at the beginning of what I think the BRN-180 will evolve to, and I’m excited to see where it ends up. With the continued growth in popularity, I expect to see more and more aftermarket parts become available. I don’t think this product is going to die off anytime soon.

Do you have any experience with the BRN-180? If so, let me know your thoughts in the comments!

Written by: Kurt Martonik

Kurt is a Gunsmith, Reloader, Hunter, and Outdoorsman. He grew up in Elk County, Pennsylvania, where he became obsessed with the world of firearms. Following high school, Kurt enlisted in the United States Air Force as a Boom Operator, where he eventually rose to the position of Instructor. After his military service, he attended the Colorado School of Trades(CST) in Lakewood, CO for gunsmithing. Following graduation, he accepted a job at C. Sharps Arms in Montana, where he worked as a full time stockmaker and gunsmith.

I have a BRN-180 Gen 2 W-7.62X39 16 inch Barrell, I have know complaints ,it’s a fine rifle indeed ! Well made lifetime warranty from Brownells can’t beat that, period !!! However it does need two things in my opinion a descent forward handgaurd or fore-guard cover/grip ? And a different Bolt handle as I find the cheap wire looking bolt handle not very user friendly as it hangs easily through heavy brush & weeds & it to me has way to much free play & is slippery as well to me ? Anyways their aren’t either available yet that I know of ! But that front gets hot after 50 + rounds unless you wrap it or put on a front grip onto the rail which I find way to aggressive formyneeds asi shoot of a bench a lot & sent gonna seeAny combat anyhow with the rifle ? I do wish the BRN-180 came with or in the future can buy a 18-20 inch barrel for the7.62X39 it does help tighten up groups in spite of what the ballistic experts say ? They state that 16 inch is max on the burn time on the propellant but I have found that a 18 inch 7.62 X 39 barrel tightens it down too less than 2-inches @ 100 yards once the barrel is properly broken in ? The 16 inch is about 3-inch @ 100 yards based on the research I’ve done ? I had a PolyTech Legend Series Sniper Version Chinese type 56 w/milled reciever w/20 inch.barrel & it would do 2 inches or less @100 yards with standard chicom military 122 grain ! That rifle is built to the highest standards by poly technologies witch is military grade weaponry! They made a M14 20 years ago all though a metric version, of the standard 1960-1970’s GI M14 in 7.62X51 NATO or .308 Winchester that once broken in & loading up with its favorite ammo would do 2-3 inches with the skinny metric barrel it came with, that was quite smaller in diameter than the standard US GI M14 Rifle it was chrome lined as well ! You either got a good one or one that needed some work to perform though ! I said all of this too say that if a mass produced Chinese military rifle can be designed & manufactured to perform & last then one would think that a fine company like Brownells who makes & designs a wonderful & great rifles & parts can & does do much better than a Chinese military grade rifle ever could ! Now I know the Legend Type 56 milled reciever Sniper AK 47 with a 20 inch barrel can do 2-inches then a Brownells BRN-180 Gen 2 in any barrel length should do less than 2-inches @ 100 yards anyday ? So can you get them to offer longer barrels for us guys who buy ours to shoot & hunt not for combat get them too add the 18-20 inch barrel option I’m not just the 223 but in the 300 & the 7.62 X 39 BRN-180 ? I will gladly pay to have mine rebarrelled in 18 inch when available in 7.62X 39 & also they need to offer a designated 22 caliber BRN-180 upper like the present 9mm version they are offering ! I would take two a pistol & rifle 22 upper ! Keep up the good work folks !

Thank-You !

Sincerely & Respectfully !

John D Watson

Hi John, I agree with you on both of those recommendations, the handguard gets HOT! A lot of people are wrapping suppressor heat shields around them and getting away with it that way. The charging handle was designed to replicate the original AR-180 ones, for awhile there they offered a straight sporter style one, but I’m not sure what happened to that one.

As far as barrel length options go, I can pass along your recommendation!

-Kurt