Any information provided in this article is purely for educational and entertainment purposes and should not be considered professional advice. It is important to note that the accuracy and reliability of the information presented is sourced from Maj Gen Julian Hatcher’s book, Hatcher’s Notebook. Ultimately, the responsibility for any decisions made based on the content of this article lies solely with the reader, and I cannot be held liable for any actions taken based on this information. Every firearm should be inspected by a qualified gunsmith prior to firing.

I had always heard rumors that there were some Springfield 1903 rifles that were not safe to shoot. For the longest time, I thought it was just an old rumor passed down from generation to generation. However, while attending gunsmithing school at the Colorado School of Trades, the subject came up again.

Throughout the service life of the American Springfield 1903 Rifle, there were a number of rifles that had the receivers burst due to faulty heat treatment. However, this was acknowledged, and changes were made, making the receivers much stronger. Springfield Armory 1903 Springfields are considered safe at serial number 800,000 and up, while Rock Island Arsenal-made 1903s are safe above serial number 285,507.

Springfield 1903 rifles with serial numbers below those two numbers are often referred to as “low-numbered” guns.

Affiliate Disclosure: This article may contain affiliate links. When you use these links, I earn a small commission from each sale generated at no cost to you. This commission helps me continue to put out free content. I work a full-time job that I am very happy with; therefore, I don’t need this commission and am not obligated to speak highly of any product. Everything written is my own opinion: the good, the bad, and the ugly.

Is Your Springfield 1903 Safe to Shoot?

The Springfield 1903 served the United States military throughout World War I, World War II, and the various other conflicts in between often referred to as the “Banana Wars.” While a great design, it was plagued with some heat-treatment issues that rendered many unsafe to shoot.

Your Springfield 1903 rifle is considered safe to shoot if it was made after the heat treatment issues were fixed. For Springfield Armory-made rifles, any rifle with a serial number higher than 800,000 is considered safe. For Rock Island Arsenal-made rifles, any rifle made after serial number 285,507 is considered safe.

“On February 20, 1918, at rifle No. 800,000, a major change was made in the heat treatment of the receiver and bolt, which resulted in a rifle of far greater strength than before.

-Maj. Gen. Julian S. Hatcher, Hatcher’s Notebook

On May 11, 1918, at receiver No. 285.507, Rock Island Arsenal adopted an improved heat treatment for carbon steel M 1903 receivers and bolts.”

While the heat-treatment process was considered fixed after those serial numbers, it is important to note that a very small number of the faulty receivers were, in fact, found after these serial number ranges. Out of the 68 burst receiver incidents, 2 of them occurred with receivers in the “safe range” of numbers. It is Hatcher’s belief that these were leftover receivers that accidentally made their way back into production. The risk is extremely low for those rifles.

| Make/Model | Serial Number Range of Concern | Safe to Shoot |

| Springfield Armory M1903 | 0-800,000 | No |

| Rock Island Arsenal M1903 | 0-285,507 | No |

What about the 1903A3? Are They Safe?

The M1903A3 Springfield rifle was made long after the heat-treatment issues occurred and is considered safe to shoot, assuming the rest of the rifle is in serviceable condition. They were made using the newer nickel steel, and there have been no reports of any similar issues occurring with them.

How Strong is the Springfield 1903 Action? Designed to Fail

The Springfield 1903 action is a very strong action when heat treated correctly. Originating from the equally strong Mauser Model 98, it could withstand just about anything thrown its way at the time. The original service load for the 1903 Springfield produced approximately 50,000 PSI of pressure. Each rifle was tested using “blue pill” proof loads starting at 70,000 PSI and later raised to 75,000 PSI.

“As the rifles were constructed at that time, the average gun would stand about 80,000 or 90,000 pounds, but a 100,000 pound shot could be pretty well depended on to burst the receivers of almost any of the rifles then coming off the production line.”

– Maj Gen Julian S. Hatcher, Hatcher’s Notebook

Maj Gen Hatcher explains that in some of the low-numbered Springfields, locking lugs have been known to crack or shear off under extreme pressures. However, in all of those cases, the design of the Springfield, specifically the safety lug, kept the bolt in the rifle and did not allow it to injure the shooter.

Related Article: The Complete History of the Lyman Alaskan Scope

The Springfield 1903 is Stronger Than You Think

To further test this, Hatcher reduced the size of the recoil lugs by half and again tested them to failure. Still not satisfied, he removed the locking lugs entirely, solely relying on the safety lug. While testing with the high-pressure blue pill loads, the safety lug withstood the pressure and only moved rearward half an inch before locking up.

There is a lot of evidence to suggest that inconsistencies in the ammunition of the day were the cause of most of the M1903 Springfield problems. However, those ammunition problems helped identify and correct the improper heat treatment found in the early receivers.

Use coupon code KTG10 to get 10% off your order of $150 or more at Brownells.

Believe it or not, rifles are designed to fail. Admittedly, designed to fail might be a little off. They are designed to handle failure and protect the shooter. Even in the cases where the improperly heat-treated receivers burst, Maj Gen Hatcher admits that if the shooters had been wearing eye protection, they would have been uninjured.

More Than Meets the Eye… Literally

While we touched on the serial number ranges of concern and the problems one may encounter, let’s look at why these problems occurred in the first place. Before taking a look at this, we have to take into consideration the time period in which these problem receivers were made, 1902-1918. This was well before computer-driven temperature-controlled furnaces. Much of the manufacturing process relied on highly-skilled labor.

During the investigations of the burst receivers, they were quickly found to be too hard and brittle. This was later verified by Hatcher by simply putting receivers in a vise and hitting them with a hammer. The brittle ones would shatter, while the properly heat-treated ones would withstand the blow without issue. Using his knowledge acquired at Ordnance School, Hatcher could tell that these were being overheated.

Related Article: Does Refinishing a Gun Hurt Its Value? Or Help It?

When steel becomes too hot during the heat treatment process, it changes the steel’s structure on a microscopic scale. Maybe not microscopic, as it can be seen by the trained eye. Hatcher states that, “The fine crystalline structure that gives it its strength becomes ruined, and the metal separates into large, coarse grains with a gaseous film between them which takes away their power of cohesion and makes the steel weak and brittle.”

The steel was simply getting too hot during the heat-treatment process.

At that time, the armories and arsenals were too reliant on the experience of their skilled labor force in the forge shop. As you can see from the quote below, the workers, much like today, weren’t too fond of change.

-Maj Gen Julian S. Hatcher, Hatcher’s Notebook

“These men thought that they could tell when a piece had the right heat just by looking into the furnace. They were proud of their ex-perience, skill, and ability, and believed that it took years of practice to become expert in judging the forging temperature. They were highly paid craftsmen, who were jealous of their exclusive skill, and who both hated and feared these new fangled pyrometers which threatened to make useless their special knowledge.”

Now here is where it gets interesting. Once the metallurgist installed the pyrometers to better gauge the heat inside the furnaces, what they found was astounding. Those old timers that were judging the furnace temperature by eye were getting receivers 300 degrees hotter on a bright sunny day than on a dark cloudy one!

You read that right. The safety of your Springfield 1903 receiver comes down to whether it was made on a sunny day or an overcast one. Today, this seems crazy to think that the weather had that much effect on the manufacturing process, but we have to remember that large-scale electricity only began a few years before the M1903 came into being.

The New Heat Treatment Process

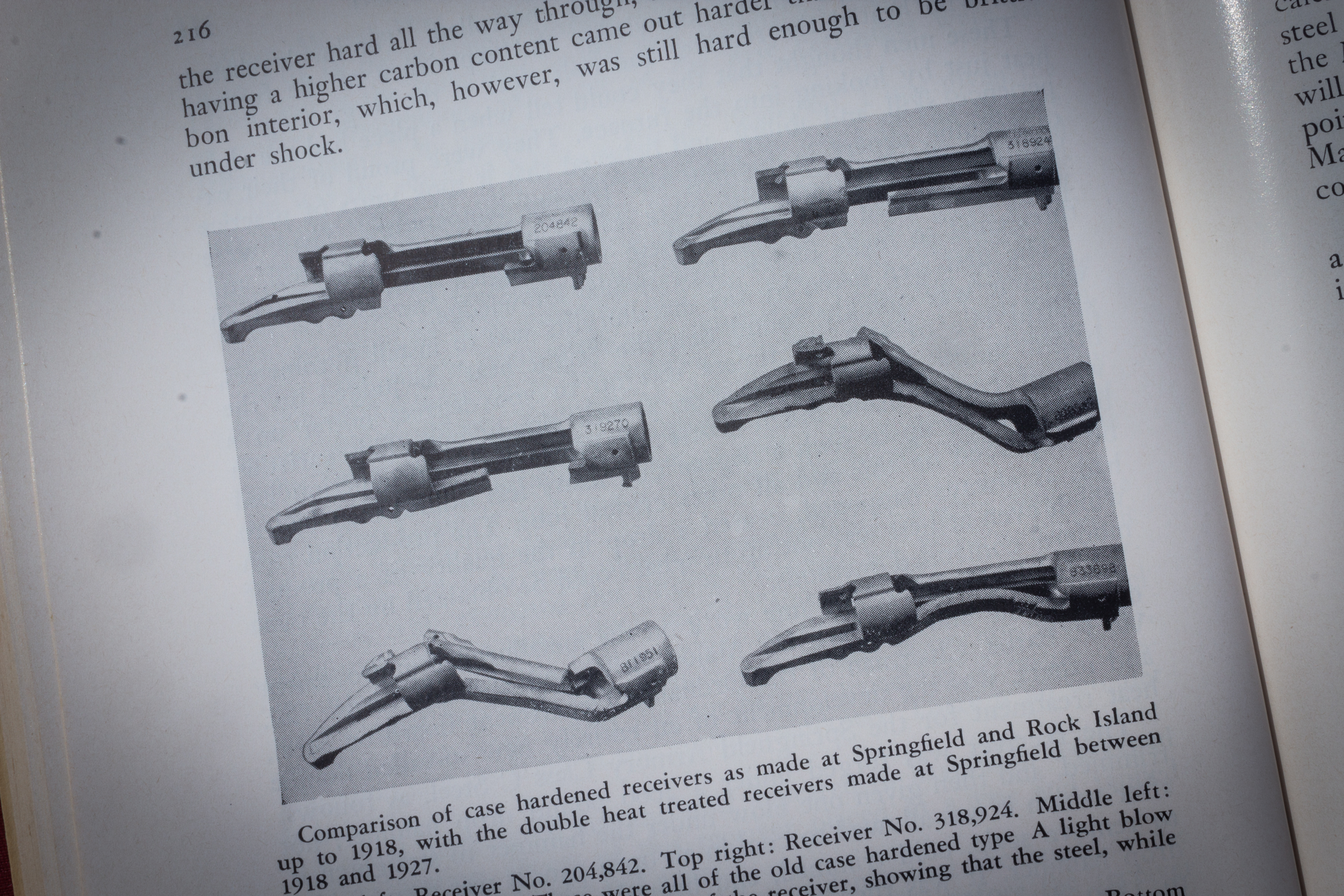

Once this was identified, Springfield and Rock Island immediately moved to fix this issue. Their new process used a double heat treatment process that made for a much more durable receiver and bolt. They heated the receivers and quenched them at a slightly lower temperature than before.

This new process essentially created a case-hardened receiver as opposed to a through-hardened one. The case-hardened receiver had a hardened outer layer giving it the majority of its strength but a softer core. This softer core was a critical component when a failure occurred as it would stretch and move instead of break.

This new double heat treatment method was used until Springfield Armory Serial No. 1,275,767 and Rock Island Serial No. 319,921 when new nickel steel began being used for the receivers and bolts. This new steel was stronger than the WD 1325 steel originally used.

What To Do With Those Springfields Made on Sunny Days

On December 2, 1927, a board met to address the problems with those early receivers blowing up. They had a challenging decision to make. Despite the large number of incidents that occurred with the early serial-numbered guns, many had thousands of rounds through them and haven’t had a single issue. Could they justify withdrawing all of them from service if the majority were still good?

The problem lies in the fact that there is no way to identify which individual rifles in that serial number range were not heat-treated properly. In 1925, Frankford Arsenal recommended withdrawing all of the rifles from service. Again in 1926, Frankford Arsenal requested that all low-numbered rifles be prohibited from firing small arms ammunition at all. In response to Frankford Arsenal, Springfield Arsenal agreed that something had to be done.

The Army’s Policy on the M1903

Many attempts were made to simply reheat-treat the affected receivers. However, that didn’t solve the problem, and they still had strength issues. On February 7, 1928, Chief of Field Service Brigadier General Samuel Hof made the following recommendation, which was approved as a policy;

“Our ammunition is getting worse, and accidents may be somewhat more frequent. On the other hand, some of these early rifles have been in use for many years, and undoubtedly, some of them have worn out several barrels. I do not think the occasion merits the withdrawal of the rifles of low numbers in the hands of troops until the rifle is otherwise unserviceable. On the other hand, I do not think we are justified in issuing such rifles from our establishments. I recommend that we instruct our Ordnance establishments to no longer issue rifles with these questionable receivers, that such rifles be set aside and considered as a war reserve, and the question of the ultimate replacement of the receivers be deferred. When rifles are turned in from the troops for repair, the receivers having these low numbers should be scrapped.”

Final Notes on the Springfield 1903 & Hatcher’s Notebook

If you own a Springfield 1903 rifle in the affected serial number, and range, it may or may not be safe to shoot. It should be noted that out of the 1,285,507 rifles that were produced before changing the heat-treatment process, only 68 receivers burst. And it is no secret that most of the malfunctions were due to ammunition flaws and the extreme pressures that they produced. Today, our ammunition today is much better quality and held to a much higher standard.

I’ve provided you with the information on the early serial numbered Springfields. Make an educated decision on whether you should shoot yours or not. There are many options available outside of that serial number range that are completely safe to fire. I encourage anyone to do so.

Much of this article stemmed from information provided by Major General Julian S. Hatcher in his legendary book Hatcher’s Notebook. This book is a wealth of knowledge about turn-of-the-century arms and the testing that they did to prove and disprove various theories. It is a must-have for any gun/gunsmithing library.

I hope this article helped you evaluate the safety of your Springfield M1903.

Written by: Kurt Martonik

Kurt is a Gunsmith, Reloader, Hunter, and Outdoorsman. He grew up in Elk County, Pennsylvania, where he became obsessed with the world of firearms. Following high school, Kurt enlisted in the United States Air Force as a Boom Operator, where he eventually rose to the position of Instructor. After his military service, he attended the Colorado School of Trades(CST) in Lakewood, CO for gunsmithing. Following graduation, he accepted a job at C. Sharps Arms in Montana, where he worked as a full time stockmaker and gunsmith.