Your barrel’s twist rate is important when trying to stabilize bullets of different weights. Sooner or later, when you get deep into the world of reloading, you will want to know your rifle’s twist rate. The measurement is very simple and can easily be done at home with what you already have on hand.

In many cases, the twist rate is not marked on the barrel and must be measured. Do this by attaching a clothespin to your cleaning rod and measuring the distance it takes to go one rotation. That distance will equal your twist rate.

This is one of the easiest tricks in the book and can be done at home!

Affiliate Disclosure: This article may contain affiliate links. When you use these links, I earn a small commission from each sale generated at no cost to you. This commission helps me continue to put out free content. I work a full-time job that I am very happy with; therefore, I don’t need this commission and am not obligated to speak highly of any product. Everything written is my own opinion: the good, the bad, and the ugly.

What is Twist Rate?

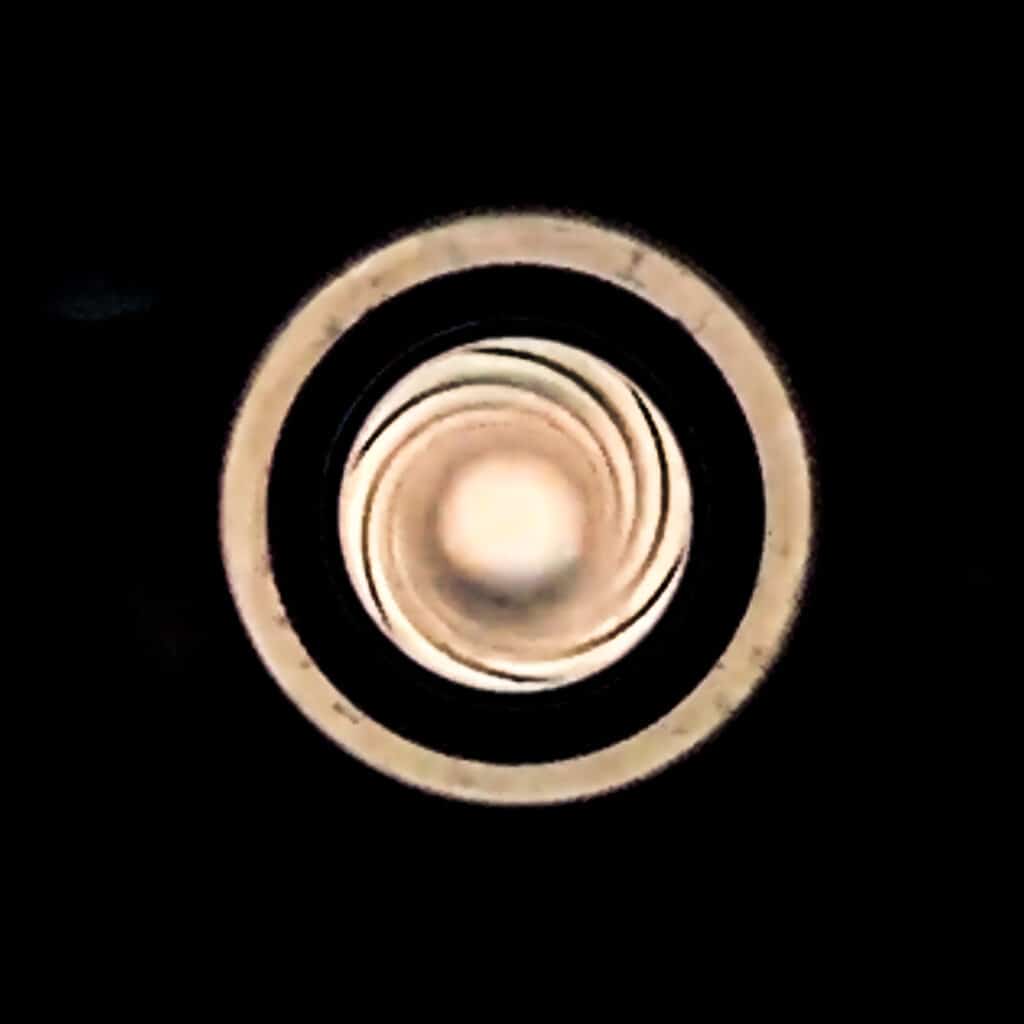

Twist rate refers to your rifling(the spiral grooves inside your gun barrel) and the distance that it takes to make one complete 360-degree rotation. This measurement is almost always presented as a ratio such as 1:12 or 1:9. The first number will always be a “1”, representing one rotation. The second number will be the distance in inches that the rifling makes one full rotation. A 1:12 ratio is read as “one and twelve twist,” meaning your bullet will make one full rotation in twelve inches.

The rifling’s twist rate is essential to stabilize a bullet. The rifling makes the bullet spin as it goes down the barrel, increasing both stability and accuracy. If the twist rate is not correct for the bullet weight you are using, you can make your bullet tumble through the air and “keyhole” targets.

Why Would Anyone Need to Measure A Rifle’s Twist Rate?

The rate at which your rifling twist plays a big part in the accuracy and stability of your bullet. Where this really applies is for the reloader looking to use heavy-for-caliber high ballistic coefficient bullets. Knowing the twist rate of your rifle helps you choose the right bullet weight for your rifle.

In general, bigger diameter short bullets need a slower twist rate, while longer, heavier bullets need a fast twist rate. If you are loading for a .223 or 5.56, your rifle with a 1:12 twist may not be as accurate as it can be with 62-grain bullets. The U.S. Military identified this decades ago. The original M-16 had a 1:12 twist rate which was perfect for their 55-grain projectile. When they switched to the 62-grain bullet, they had to change the twist rate to 1:7.

Tools Needed to Measure Twist Rate

- Cleaning Rod – I prefer to use one with ball bearings in the handle, allowing it to rotate freely. This Dewey cleaning rod has done well for me over the last couple of years.

- Cleaning Patch – A snug-fitting patch is a must, as it needs to engage the grooves.

- Clothes Pin – Available anywhere.

- Tape Measure – A yardstick works well too.

How To Measure

Insert the cleaning rod and patch into the barrel an inch or two. Again it is important to have a proper fitting patch that fully engages the rifling, or it may not work correctly.

Attach the clothespin to the end of the cleaning rod near the handle. I clamp this on so that the tail is oriented vertically toward the ceiling.

Measure how far the clothespin is from the barrel and write it down. I will try and get this to land on a whole number and will adjust the clothespin accordingly. The measurement can be taken from any point on the rifle that remains constant, such as the back of the receiver or tang.

Slowly push the patch through the bore. It is best to use a cleaning rod where the handle rotates freely. If you don’t have one, push from the back of the handle and allow the whole rod to rotate with the rifling. You should see the clothespin start to rotate as the rod moves.

After one full rotation, measure the distance the clothespin is from your reference point. If you’re measuring a muzzleloader barrel or something that has a longer twist rate than barrel length, make this measurement at a half or quarter rotation, then multiply accordingly.

Subtract the difference. If your initial measurement is 22 inches and after one rotation, your clothespin is now 13 inches from the reference point. Your twist rate would be 1:9.

Use coupon code KTG10 to get 10% off your order of $150 or more at Brownells.

Isn’t Twist Rate Just Marked on the Barrel?

Most modern rifle and barrel manufacturers are now stamping the twist rate on the outside of the barrel to help the user. However, this is a more recent occurrence and is not found on many older rifles. Therefore, there are many times that it is necessary to measure the twist rate yourself.

Shilen Rifles, Inc has a great chart located here that has a list of the ideal twist rates for each caliber and bullet weight.

Written by: Kurt Martonik

Kurt is a Gunsmith, Reloader, Hunter, and Outdoorsman. He grew up in Elk County, Pennsylvania, where he became obsessed with the world of firearms. Following high school, Kurt enlisted in the United States Air Force as a Boom Operator, where he eventually rose to the position of Instructor. After his military service, he attended the Colorado School of Trades(CST) in Lakewood, CO for gunsmithing. Following graduation, he accepted a job at C. Sharps Arms in Montana, where he worked as a full time stockmaker and gunsmith.