The invention of the primer came along with the onset of the self-contained cartridge case. It made it possible to have a reloadable case that was previously impossible with the rimfires of the day. This centerfire primer not only helped with reloading but also allowed for better accuracy and improved reliability.

The primer is an essential component of centerfire cartridges. Located in the case head of a cartridge, it is responsible for igniting the powder charge. Primers are made up of four primary components: the cup, anvil, priming compound or mixture, and foil cover. These four components work together with the gun’s firing mechanism to set off the chain or reactions involved with firing a self-contained cartridge.

Two main types of centerfire primers are found today: Boxer and Berdan. Boxer primers are the most used type in the United States, as it is easier to reload with them. Dimensionally, the two are nearly identical but are very different internally. While both use the same components, the Berdan style used the cartridge casing as the anvil.

Understanding the primer, its history, and how it works can take your reloading to the next level and help you achieve the best accuracy of your firearms.

Affiliate Disclosure: This article may contain affiliate links. When you use these links, I earn a small commission from each sale generated at no cost to you. This commission helps me continue to put out free content. I work a full-time job that I am very happy with; therefore, I don’t need this commission and am not obligated to speak highly of any product. Everything written is my own opinion: the good, the bad, and the ugly.

The History of Centerfire Primers

The invention of the self-contained cartridge brought about many innovations in the cartridge world. Starting with rimfires, the cartridges eventually evolved into centerfires. Initially, these centerfire cartridges were internally primed. In 1877, the U.S. Army developed the first externally primed 45-70 Government cartridge. Although it took another five years to adopt, it was groundbreaking. Like most military small arms developments, it caught on quickly in the civilian market, and this “new” external priming is considered the norm today.

External priming allowed for a couple of things: improved reliability and the ability to reload the spent casing. This was a huge advantage to the U.S. Army, which had troops spread all over the western frontier, manning remote forts and trading posts. Soon thereafter, reloading kits and components were issued to many units, allowing them to supplement their slow wagon train supply lines.

As this caught on, new innovations took place. Ultimately, it resulted in us having two main types of primers across the globe. Berdan and Boxer. Boxer-type primers are what you see on the shelves at your local sporting goods store in the U.S., while Berdan is mostly found in military surplus and foreign-made ammunition. These two have been the world standard for small arms.

Primer Composition

Primers consist of four main parts:

- Cup – This is the external “shell” you see at the bottom of a cartridge. It is essentially a capsule that holds the other priming components. Cups vary in thickness from manufacturer to manufacturer, sometimes causing what many refer to as a hard primer. Their size designates whether they are large or small-sized primers. Cups have been made of copper, nickel-plated copper, brass, copper alloy, cupronickel, and sometimes zinc-coated steel.

- Priming Mixture – Inside the cup, you’ll find the priming compound. This differentiates rifle primers from pistol and magnum primers. Different priming mixtures can achieve hotter or longer burn rates. As far as the chemical mixture goes, Outdoor Life has an excellent article about this that can be found here. This compound is ignited through pressure and compression.

- Anvil – The job of the anvil is to provide enough resistance against the firing pin during the firing sequence to detonate the priming compound reliably. While it works the same in both types of primers. The Boxer style has the anvil built into the primer, while the Berdan has it built into the brass or steel casing. Next time you are at your reloading bench, pick up one of the spent primers you likely have lying on the floor. The little three-winged flat piece you can see on top is the anvil.

- Foil Cover – Essentially a drop of lacquer, the foil cover sits between the priming compound and the anvil. Its job is to protect the priming compound from contamination.

How Primers works

When the trigger is pulled, the firing pin strikes the center of the primer cup. The force of the firing pin compresses the priming compound against the anvil, setting off the fuel and oxidizer. A jet of flame is shot through the flash hole, igniting the powder charge.

Berdan vs. Boxer Primers

Boxer primers are the most common type of primer used by handloaders and ammunition manufacturers. Introduced in 1866 by Col. Edward Boxer of the Royal Arsenal in England, it contained four main components: the cup, priming compound, anvil, and foil cover.

Across the ocean in the same year, American Civil War General Hiram Berdan invented the Berdan primer. This three-piece design is still widely used overseas in military ammunition. The three components are the cup, priming compound, and foil cover. The anvil is contained in the cartridge casing.

Use coupon code KTG10 to get 10% off your order of $150 or more at Brownells.

Aside from the anvils, the other main difference between the Berdan and Boxer primer systems is the flash hole arrangement. The Berdan system uses two flash holes, while the Boxer has only one that is centrally located. There have been arguments about which is more reliable/accurate/etc. but I have found them to perform equally well. For practical purposes, reliability and accuracy are indistinguishable. Boxer primers are so popular here in the states because of the ability to easily reload them. While it is possible to reload Berdan-style casing with the use of special tools, it isn’t practical.

To reload Berdan cases, you convert each casing to a Boxer-style priming system by drilling a center flash hole and removing the integral anvil. The tooling necessary can be expensive and time-consuming to use, pushing many people away from it. There are also places like fedarm.com that sell Berdan primers, but the issue still remains in the specialized tooling to remove the spent primers.

Before continuing with this next section, you need to understand that this is just a guide and is no substitute for a reloading manual. Reloading manuals are trusted because they have extensive testing to back them up and provide safe loading data. While some primers may interchange for different cartridges, they can drastically change pressures and potentially lead to an unsafe situation. Follow your loading manual!

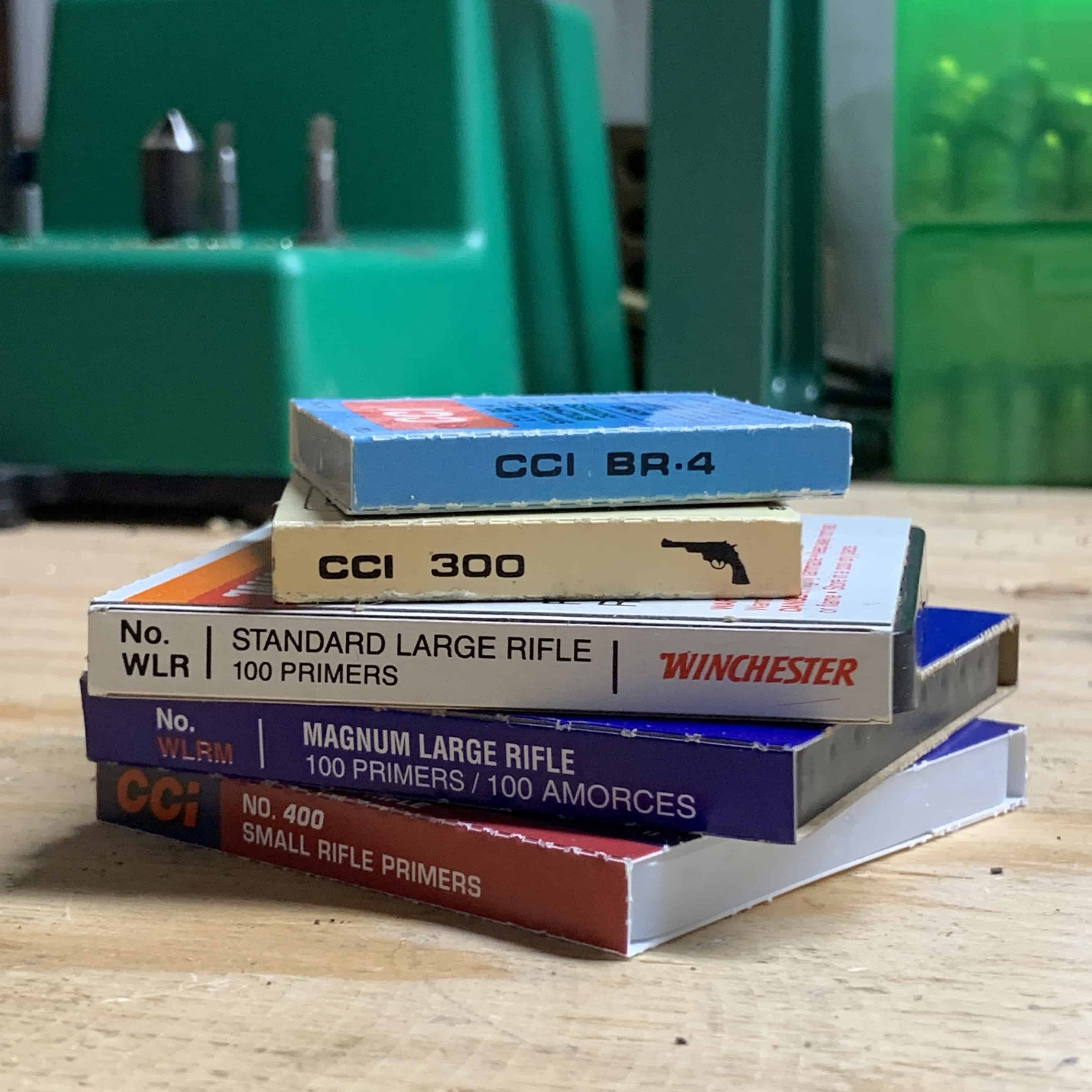

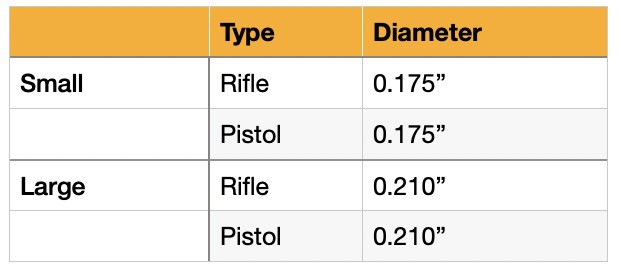

Types of Primers & Sizes

Primer sizes and types can be very confusing to new reloaders. With so many variations out there, it is good to have a guide to go by. It should be broken down into a few sections to fully understand what each derivative means. These sections are pistol, rifle, magnum, and match/benchrest. Shotgun Primers will be covered in a separate section.

Pistol Primers

The pistol primer is designed to work most efficiently in a pistol cartridge. The cup size is dimensionally the same externally as rifles, but the cup thickness is usually thinner. What does that mean? Pistol primers aren’t designed to withstand some of the high pressures that a centerfire rifle can produce. This reduced thickness also means that they are easier to ignite and may come in handy when operating firearms with light-firing pin strikes.

Rifle Primers

Comparatively, the cup of a rifle primer is thicker than the pistol primer and is designed to withstand the higher pressures of rifle cartridges. While only having minor differences, rifle primers can be loaded in pistol cases of the same primer pocket size and vice versa. Consult your reloading manual! How does this apply? You’ll run into this using cut-down or resized brass of another cartridge to make oddball calibers.

Magnum Primers

Magnum Primers come in all the above shapes and sizes: rifle, pistol, small, and large. So what is the difference? Magnum cartridges tend to have large amounts of slow-burning, hard-to-ignite powder. The magnum primer was designed to counteract this by producing a more intense heat upon ignition. This leads to higher pressures. Once again, consult your reloading manual before putting magnum primers into your standard loads.

Match & Benchrest

The Benchrest community is pushing the limits of accuracy daily, and these primers are critical to their reloads. To get accuracy, you need consistency. To get consistency in manufacturing, you need high standards of quality control. Match and benchrest primers are held to a higher standard of testing and quality control, giving you a more consistent product. They don’t differ in composition from the other types described, so they can be interchanged freely as long as they are within the same size and type.

Shotgun Primers

Lastly, we have shotgun primers. They are constructed differently than rifle and pistol primers and are not interchangeable. Shotgun primers are constructed with an integral anvil, just like boxer primers. They are broken down into two main categories: Hot and Mild. Most people never find themselves needing anything beyond mild when reloading shotgun shells. The design of the shotgun primer leads them to be used in many inline muzzleloaders.

Care in Reloading

Storage is the first thing to consider. Your Primer is the heart and soul of your cartridge and should be treated as such. Much like other components to reloading, storage is key. Extreme heat, humidity, and cold can negatively affect your primers. Varying temperatures can dry out the priming compound, causing reliability issues. You need to take this into consideration when storing your primers.

Therefore, limiting the amount of exposure to both on the reloading bench is important. For me personally, that means dumping the primers right into the primer tray of my RCBS hand priming tool. By doing this, my hands never touch the exposed primer, greatly reducing my chances of contamination from the oils on my fingers.

Read other related articles about ballistics here!

Written by: Kurt Martonik

Kurt is a Gunsmith, Reloader, Hunter, and Outdoorsman. He grew up in Elk County, Pennsylvania, where he became obsessed with the world of firearms. Following high school, Kurt enlisted in the United States Air Force as a Boom Operator, where he eventually rose to the position of Instructor. After his military service, he attended the Colorado School of Trades(CST) in Lakewood, CO for gunsmithing. Following graduation, he accepted a job at C. Sharps Arms in Montana, where he worked as a full time stockmaker and gunsmith.