If you have ever come across a firearm that you are unsure of what it is chambered in and it isn’t marked correctly, pouring a chamber case using Cerrosafe is the best option.

Cerrosafe is the easiest product to use when making a chamber cast. Its low melting point and minimal shrinkage make it ideal for getting an accurate look at your chamber. This process is as simple as wiping the bore dry, plugging the barrel with a patch, and pouring the Cerrosafe into the chamber.

Pouring a chamber cast is simple and can easily be done at home with the proper tools!

Affiliate Disclosure: This article may contain affiliate links. When you use these links, I earn a small commission from each sale generated at no cost to you. This commission helps me continue to put out free content. I work a full-time job that I am very happy with; therefore, I don’t need this commission and am not obligated to speak highly of any product. Everything written is my own opinion: the good, the bad, and the ugly.

What is Cerrosafe

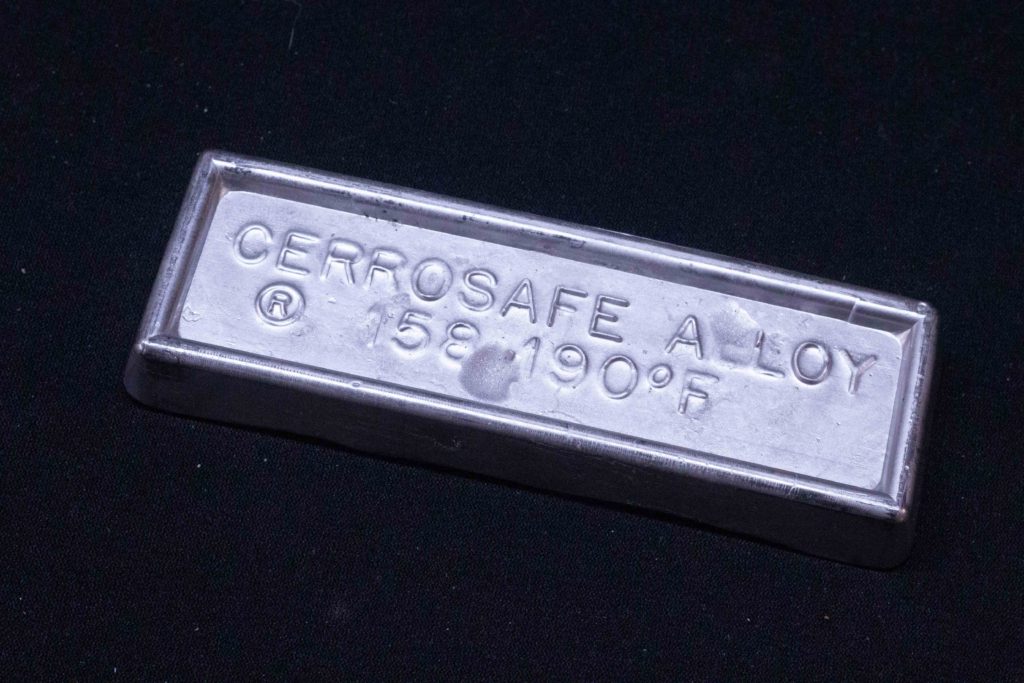

Cerrosafe is a casting alloy that is primarily used to get the interior dimensions of a chamber or throat. It is a mixture of Bismuth, Lead, Cadmium, and Indium. It works well for rifle, pistol, and shotgun chambers and has many other applications in the shop. The low melting point (158-190 Degrees F)of Cerrosafe makes it a favorite of gunsmiths and allows for a quick job.

Cerrosafe shrinks slightly while cooling, allowing for easy removal from the chamber. However, since most people use Cerrosafe to get accurate measurements of a chamber, this would typically be a problem. The characteristics of Cerrosafe make it expand back to its true size after one hour of cooling. Brownells, Inc. states that after cooling for 200 or so hours, the cast will expand about .0025″ of an inch.

The other benefit of Cerrosafe is that it is completely reusable and can be used over and over again as long as it isn’t overheated.

Tools Needed

Cerrosafe – Found at Brownells.com in 1/2 lb and 1 lb ingots.

Cleaning Rod – A stiff cleaning rod that is long enough to reach just in front of your chamber.

Cleaning Patch – A tight-fitting cleaning patch to plug the bore. These can be doubled up if necessary.

Calipers – A pair of calipers is a necessity if trying to identify an unknown caliber.

Heat Source – Propane torch or hot plate.

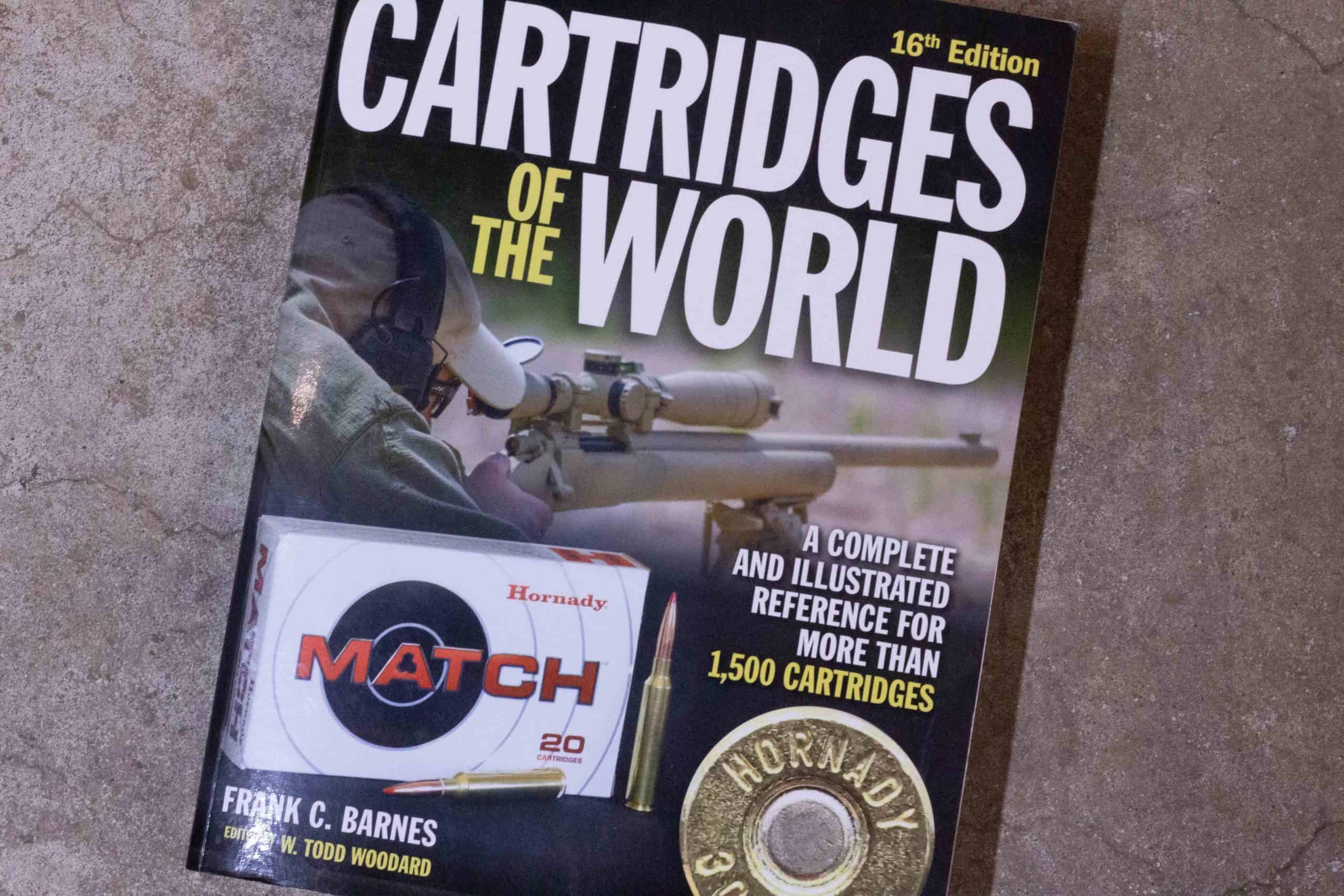

Cartridges of the World – This book is an excellent resource that has dimensional data of just about every caliber known to man.

Chamber Cast Pre-Checks

Making a chamber cast is best done with the barrel removed from the action. However, that is not necessary and is rarely the case. If making a cast from a barreled action, make sure to inspect the chamber and action area for any places that might lock your casting in place. This will save you the pain of getting a casting stuck in the chamber.

Use coupon code KTG10 to get 10% off your order of $150 or more at Brownells.

How to Make a Chamber Cast

- Disassemble the firearm so that you have good access to the chamber area. Take it out of its stock if applicable.

- Clean the chamber using a dry cotton patch and cleaning rod. Pistol cleaning rods with a looped end really work well for this.

- Plug the bore using a tight-fitting patch and cleaning rod. Measure the approximate distance to the end of the chamber area or visually check that the plug stops 1/2″- 1″ shy of the chamber area. I insert this patch or plug from the muzzle end of the barrel.

- Position the barrel vertically in a bench vise to allow for a clear entrance to the chamber. Heat the chamber area of the barrel until it is uncomfortable to touch.

- Melt the Cerrosafe in a metal ladle that has a pour spout. Take care not to overheat.

- Pour the Cerrosafe into the chamber until a slight mound builds up at the back of the chamber.

- Let the casting cool for a minute or two.

- Remove the chamber casting using a cleaning rod inserted from the muzzle end of the barrel. I insert the cleaning rod and simply drop the barrel an inch or two onto the end of the cleaning rod. One or two drops will normally do the trick. I don’t use my premium cleaning rods for this, but you should use one with a protective coating to avoid damaging the bore. Brownells recommends removing it within 30 minutes of pouring the casting.

- Measure the casting exactly 1 hour after pouring for the most accurate results. Measuring as soon as you remove it will get you close enough to identify an unknown caliber most of the time.

Measuring & Identifying the Cerrosafe Casting

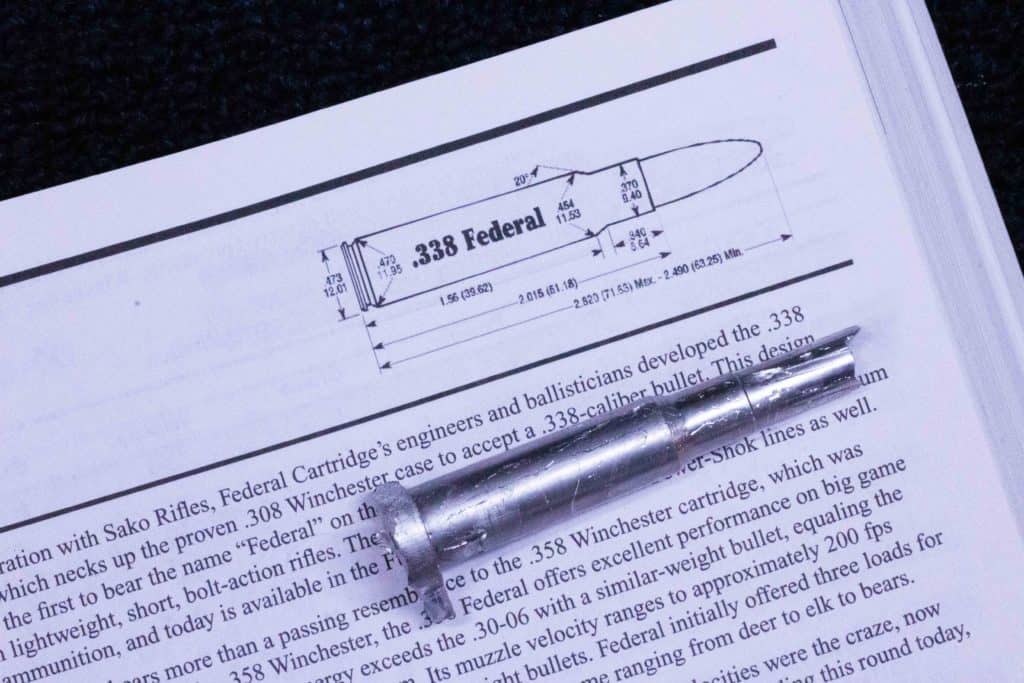

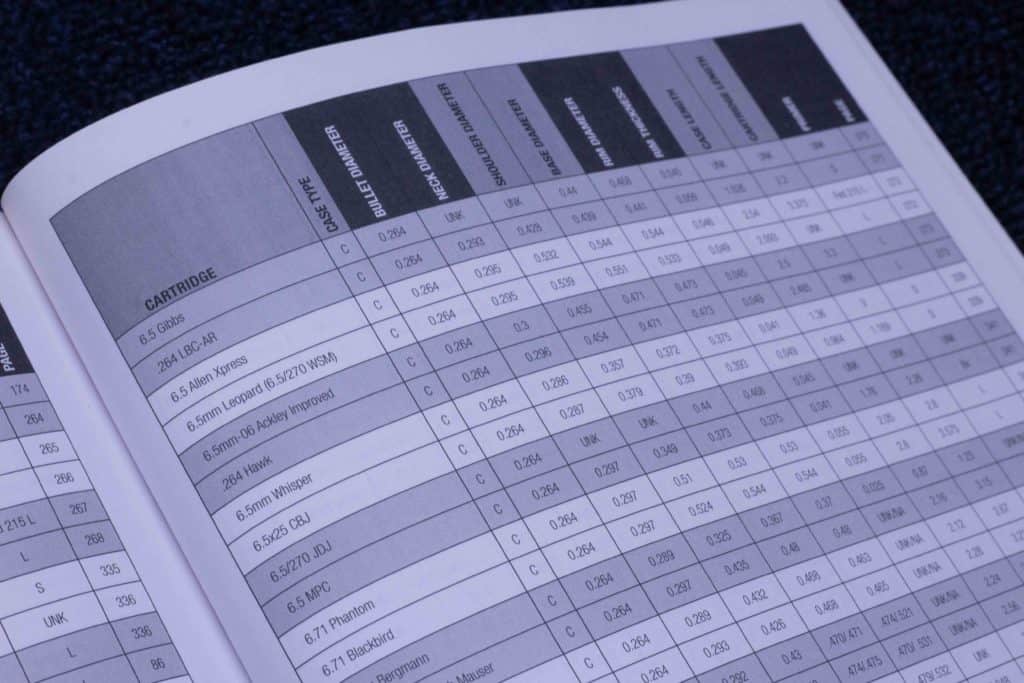

To identify the cartridge, first, find the bore diameter of the barrel. You can usually get this measurement on the front portion of the casting. Chapter 12 of Cartridges of the World has a chart with all of the measurements for all of the cartridges, and it is first organized by bore diameter. I find the next best dimension to measure is the base diameter. This will eliminate a lot of the options, and with a few more measurements, you’ll easily be able to find the cartridge. It is important to keep in mind that the chamber will be slightly bigger than the dimensions published.

Read More Gunsmithing Articles Here!

Final Notes on Cerrosafe

Cerrosafe is a great addition to any shop. It has many uses and can be used over and over again. With a few additional tools, it can tackle many jobs, such as chamber casting and removing stuck shell casings. Lastly, there is nothing out there on the market that makes the job this simple.

Written by: Kurt Martonik

Kurt is a Gunsmith, Reloader, Hunter, and Outdoorsman. He grew up in Elk County, Pennsylvania, where he became obsessed with the world of firearms. Following high school, Kurt enlisted in the United States Air Force as a Boom Operator, where he eventually rose to the position of Instructor. After his military service, he attended the Colorado School of Trades(CST) in Lakewood, CO for gunsmithing. Following graduation, he accepted a job at C. Sharps Arms in Montana, where he worked as a full time stockmaker and gunsmith.