Gun bluing is not just for looks. It has been used for centuries and provides a layer of protection for the raw steel used in many gun parts. Some methods can be done at home, while others are much more challenging and require expensive equipment.

There are five methods of gun bluing that gunsmiths use today. Each has its own advantages and disadvantages; knowing which method to use and apply will improve the outcome and result in a fine-looking, blued metal finish.

- Hot Bluing

- Cold Bluing

- Rust Bluing

- Charcoal Bluing

- Nitre Bluing

Each type of bluing has its own strengths and limitations. Choosing the wrong method can turn your simple finishing job into an expensive repair or completely ruin the firearm. Let’s dive deeper into each type of bluing and the processes used.

Affiliate Disclosure: This article may contain affiliate links. When you use these links, I earn a small commission from each sale generated at no cost to you. This commission helps me continue to put out free content. I work a full-time job that I am very happy with; therefore, I don’t need this commission and am not obligated to speak highly of any product. Everything written is my own opinion: the good, the bad, and the ugly.

What is Gun Bluing?

In the simplest form, gun bluing is a protective finish used to shield steel parts from corrosion. The bluing part of the term refers to the deep black and blue colors produced by this type of finish. It has been used in the gunmaking trade for centuries and is largely considered a traditional finish. Although it is traditional, it is the preferred method of many gunsmiths today.

There are five different types and methods of gun bluing used by gunsmiths, each with its own varying degree of protection and coloring.

What Can and Can’t Be Blued

Before we look at each type, we must examine what can and can’t be blued. As mentioned previously, bluing is a finish used on steel. These same methods will not work on other metals commonly found in firearms, such as aluminum, brass, and some stainless steel. Use a magnet if you are unsure what material your part is made of.

Not all methods will work for every application, even plain old carbon steel. There is more to consider once you identify that it is steel; these considerations are specific to each type of bluing and will be mentioned in the applicable sections below.

| Types of Bluing | Cost | Pros | Cons |

| Hot Bluing | $$ | Affordable, durable, can be done in volume | Expensive equipment, can melt soft solder |

| Cold Bluing | $ | Very affordable, easy to apply, great for touch-ups | Not very durable |

| Rust Bluing | $$$ | Arguably the most beautiful, durable | Time-consuming process |

| Charcoal Bluing | $$$$ | Beautiful, correct for certain restorations | Time-consuming, labor-intensive, expensive |

| Heat/Nitre Bluing | $ | Great colors, easily done at home | Not very durable |

The Different Types of Gun Bluing

When looking at the five different types of bluing, we will analyze three main characteristics of each; its looks, application, and durability. It is important to note that gun bluing is not very effective against corrosion until it is paired with oil.

Despite what reputation one type or another may have, all of the below finishes can provide great results if the proper metal preparations are done. This metal prep will be covered later as it can be exhaustive in itself.

Hot Blue

Hot caustic bluing has become the industry standard for bluing. It is done by submersing your metal parts in a boiling bath of caustic salts and letting them sit for a set amount of time. This process is one of the most economical to have done but the most expensive to get set up for. The colors achieved are phenomenal and vary depending on the brand of salts that you go with.

Use coupon code KTG10 to get 10% off your order of $150 or more at Brownells.

Hot bluing has become so popular because of its ability to be done in volume. Multiple guns can be done at one time and are therefore needed by firearms manufacturers today. The limiting factor for hot bluing is its temperature. Depending on your altitude, the temperature of the tanks is between 260 and 320 degrees Fahrenheit. This is hotter than some soft solders used on double shotgun barrels and can potentially melt the solder and ruin the barrels. Rust bluing is a better option for parts with soft solder.

Another reason that hot bluing has become so popular amongst manufacturers is its durability. When combined with oil, it is an excellent rust preventative and will last a long time if cared for. It is very economical for small shops and works on a wide variety of steel. It is used in almost every gunsmith shop across the country.

Cold Blue

Cold, touch-up or instant blue can look great when applied properly. Cold blue has a bad reputation amongst most gun owners as it doesn’t provide as good results as hot or rust bluing. This can be attributed to mostly being done by the hobbyist. It is the most economical bluing method and the hardest to achieve good results.

Cold bluing is different from the other methods because it uses copper sulfate to color the steel. This solution essentially puts a thin layer of copper on the surface of the steel and then blackens that thin layer of copper. This is why guns that have been cold-blued have a certain odor to them. Because it only colors the surface, it doesn’t provide nearly the depth of color of other methods.

Cold blue can be used to blue full firearms, but the results are not comparable to the other methods listed. It is the most economical form of bluing for the hobbyist making it extremely popular and a great weekend project for the tinkerer. However, this method is best used for small parts and touch-ups. Cold-blue is the least durable of the mentioned bluing methods. Therefore, professional gunsmiths do not use cold blue to blue full guns.

The Gunsmith Kinks series of books has some excellent methods of achieving good results using cold blue. I highly recommend them and wrote a review of the book series here.

Rust Blue

When done properly, rust bluing is one of the best-looking options. It has been used for a long time and pre-dates hot-bluing methods. It has a certain depth that isn’t accomplished with hot and cold bluing techniques. Rust bluing is completed by applying a chemical solution to the steel and allowing it to form a surface rust. This surface rust is boiled and carded off using an extremely fine wire wheel. The process is repeated over and over again until the desired finish is achieved.

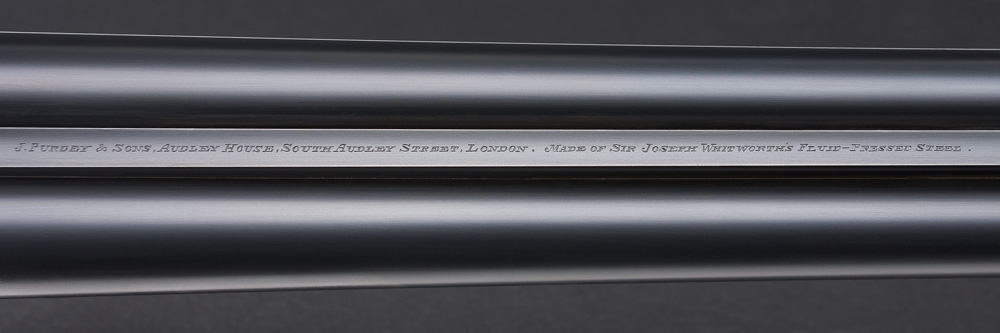

Rust blue is mostly found on older firearms that predate the use of the much more efficient hot bluing method. It is also found on high-end custom firearms, as many consider it the top of the line as far as quality is concerned. The other major use of rust bluing is for double shotgun barrels. The temperatures reached during the boiling process are below the soft solder’s, making it safe to do without the risk of the barrels falling apart.

Despite being relatively cheap to get set up to do, rust bluing is one of the more expensive methods to have done by a professional gunsmith. This process is very time-consuming and takes many hours to accomplish. The high cost is what it takes to get one of the most durable, rust-resistant, and beautiful-looking finishes out there. Rust-blued firearms have stood the test of time and will continue to do so.

Charcoal or Carbonia Bluing

Charcoal or Carbonia bluing is only a myth to most gunsmiths. It is a very time-consuming and labor-intensive method that only a few professionals have figured out. This process is commonly referred to as “Colt Bluing,” as many Colt firearms were finished using this technique before World War II. Today, this process is very difficult for a small shop to do. In the early twentieth century, The American Gas Furnace Company established a large-scale industrial application of this process, making it possible for manufacturers like Colt and Smith & Wesson to use it.

“Capturing the proper shade and texture of original charcoal bluing (sometimes referred to as machine bluing or carbona bluing) finish depends largely on the underlying metal polish. Metal parts are placed in a gas-fired furnace with animal bone and sperm whale oil, or equivalent. The end result is a hard-wearing finish with colors that vary from a blue-black (highly polished) to a lighter blue (low polish) depending on the level of polish. A charcoal blued high polished part will produce a mirror-like finish that is second to none.”

– Turnbull restoration

Today, charcoal bluing is really only used in doing period-correct restorations of older firearms and finishing fine or custom guns. It is very durable and does an excellent job of preventing corrosion. However, it is rarely offered or seen due to the complexities of completing the process correctly. This one is best left to the professionals.

Nitre Blue

Nitre bluing is a common way of bluing small steel parts such as screws and pins. Typically referred to as fire, heat, or temper bluing, this provides a unique blue color. This coloring is done by heating the metal up until it tempers to the right hue. This blue color is reached at approximately 570 and 650 degrees Fahrenheit and can be done with a propane torch, oven, or salts.

The term nitre comes from the nitre salts commonly used to do this process. Although not entirely needed, they make for a much more consistent job and will guarantee good results. This same process is often used to temper parts such as springs. Using lower temperatures, the straw-colored gold found on early luger triggers and small parts is easily achieved as well.

The common uses for nitre bluing are screws, pins, and various other small parts. Larger parts are rarely done this way as it wears relatively fast and provides no extra corrosion resistance. Additionally, heating up larger parts to those temperatures can change the tempering of the part, potentially affecting its strength and durability. It is largely used for decoration over practicality and is a really beautiful accent to other bluing methods.

Hot Blue vs. Cold Blue

Hot blue and cold blue are two very different processes that produce a blued metal finish. The hot bluing method requires a lot more equipment than cold blue does. Hot bluing refers to the process of submersing the metal parts in a hot bath of bluing salts to get the desired color. Where cold blue, the solution is wiped on without the need to heat the metal parts. Hot blue is more durable than cold blue and is the preferred method. Cold bluing should be reserved for small parts and touch-ups.

What is Gun Browning?

Gun browning is another method often used to color metal parts on firearms to mimic the finish traditionally found on muzzleloading rifles, pistols, and shotguns. By the 1700s, Colonial gunsmiths had figured out how to achieve that beautiful brown color and preferred to use it on their firearms. The brown color is a product of surface rust forming and being removed repeatedly. This brown sheen reduced the reflection of the bare steel and provided protection against the elements.

While the process is very similar to rust bluing, the solutions used differ. Many people prefer browning when restoring or building old-style muzzleloaders.

Can A Gun Be Reblued?

A gun that has its finish worn or damaged can be reblued. In fact, this is one of the most common jobs completed by a gunsmith. It is done by completely removing the old finish, degreasing the surfaces, then rebluing using one of the five methods listed above. Rebluing a firearm will sometimes hurt its value. Therefore, considerations need to be taken before having this work done. I wrote the article below to help you determine if refinishing your gun will help or hurt its value.

Does Refinishing a Gun Hurt Its Value? Or Help It?

Alternatives to Gun Bluing

Gun bluing has been used for centuries and continues to be used today. However, there are alternative ways of finishing your gun if you find that bluing isn’t the route you want to take. Cerakote, Duracoat, Alumahyde, and parkerizing are all great options for adding a protective finish to your steel gun parts. Each of these finishes has its own pros and cons that must be considered.

Cerakote, Duracote, and Alumahyde are all applied by spraying the finish on and then, in most cases, baking it in an oven. The benefits of these spray-on finishes are ten-fold. The corrosion resistance is great, and there are endless amounts of color options out there. However, gun bluing will always be the best option for restoring an old firearm back to its original glory.

If you liked this article, consider checking out my article on the types of walnut used for gunstocks!

Written by: Kurt Martonik

Kurt is a Gunsmith, Reloader, Hunter, and Outdoorsman. He grew up in Elk County, Pennsylvania, where he became obsessed with the world of firearms. Following high school, Kurt enlisted in the United States Air Force as a Boom Operator, where he eventually rose to the position of Instructor. After his military service, he attended the Colorado School of Trades(CST) in Lakewood, CO for gunsmithing. Following graduation, he accepted a job at C. Sharps Arms in Montana, where he worked as a full time stockmaker and gunsmith.