I’m a bolt-action guy. While I like all guns equally, there is something about a quality bolt-action rifle that gets me more excited than usual. The SIG Cross is no exception to this, and I was very excited to get my hands on one as I have been wanting to take an in-depth look at one since it initially came out.

The SIG Cross is a bolt-action rifle made by SIG SAUER in their Exeter, New Hampshire facility. The unique design uses a lightweight one-piece aluminum receiver in conjunction with a barrel extension for a solid lockup.

Typically, I would approach a technical article like this by only taking a look at the action itself because of the many model variations on the market. However, with the Cross, I feel that it would be incomplete without taking a look at the rifle as a whole. Because of the design, all of the stock components, forearm, and barrel are tied into the action in a unique way. If there are variations to the parts and pieces mentioned, they will be noted in the subsequent categories.

Affiliate Disclosure: This article may contain affiliate links. When you use these links, I earn a small commission from each sale generated at no cost to you. This commission helps me continue to put out free content. I work a full-time job that I am very happy with; therefore, I don’t need this commission and am not obligated to speak highly of any product. Everything written is my own opinion: the good, the bad, and the ugly.

Brownells.com sent me this rifle to test and review. Therefore, I have no connections or obligations with SIG and have the freedom to write what I want about the Cross rifle.

A Quick Overview

Before we dive into the details of each and every part, let’s do a quick overview of the SIG Cross design and what makes it differ from other bolt actions on the market. The Cross is a push-feed bolt-action design that utilizes a plunger-type ejector. It has three locking lugs lending to a short bolt throw and is fed using AICS-compatible magazines, with a few caveats that I will cover later.

As mentioned previously, the Cross utilizes a one-piece aluminum receiver in conjunction with a steel barrel extension. This design is pretty new to the bolt action world but isn’t new all around. In fact, most people are familiar with this design being used on Eugene Stoner’s AR-style rifles. This provides a very strong lockup while being able to shave weight by using aluminum.

The folding buttstock, trigger assembly, optic rail, and handguard all attach directly to the receiver, eliminating the need for a traditional stock or chassis system. This design doesn’t need action screws, therefore eliminating any accuracy issues that result from over or under-torquing them.

Use coupon code KTG10 to get 10% off your order of $150 or more at Brownells.

The stock on the SIG Cross is fully adjustable for the length of pull, buttpad position and cant, and cheek rest height. All of those adjustments are easily done by the user without any assistance. Having this adjustability means that you can mount your scope at any height and still have a solid cheek rest. However, I will say that with high Talley Modern Sporting rings my cheek rest is near the bottom of its adjustment, so you may want to think twice about using low rings on this rifle.

The handguard is attached to the receiver as well and free-floats the barrel. The handguards utilize the M-LOK attachment method and, therefore have endless options for adding accessories until your heart is content. The pistol grip is compatible with AR-15 grips, again making the options seemingly endless.

While originally targeting the hunting market, the Cross has been a popular option for competition shooting as well. SIG continues to bring new models to market year after year, adding to the versatility of the design.

| Caliber Offerings | Barrel Lengths | Twist Rate | Muzzle Thread |

| 6.5 Creedmoor | 18″, 20″, 24″ | 1:8 | 5/8×24 |

| .308 Winchester | 16″, 20″, 24″ | 1:10 | 5/8×24 |

| .277 Fury | Coming eventually… | – | – |

| 300 Win Mag | 24″ | – | 5/8×24 |

My Experience With The SIG Cross So Far

When I first picked up the SIG Cross I didn’t love it. It felt odd and thin without a scope on it, the bolt felt gritty, and it wasn’t all that comfortable. Admittedly, I’m used to the traditional styled bolt action rifle, so this was new to me. I initially wasn’t interested in comfort though, I wanted to dig deep into the design of the action and see what those masterminds of the SIG engineering team had come up with.

Within a few weeks of receiving it, I took it down to Alabama for a long-range hunting course with the guys over at Guardian Precision. I thought this would be the perfect test for a rifle that is targeted toward being a modern hunting rifle. This involved shooting at ranges from 100-750 yards from various positions and when all was said and done, I had put about 120 rounds of 6.5 Creedmoor downrange using the Cross. Its performance was flawless and I never once had a hiccup feeding, extracting, or ejecting.

Accuracy & Velocity

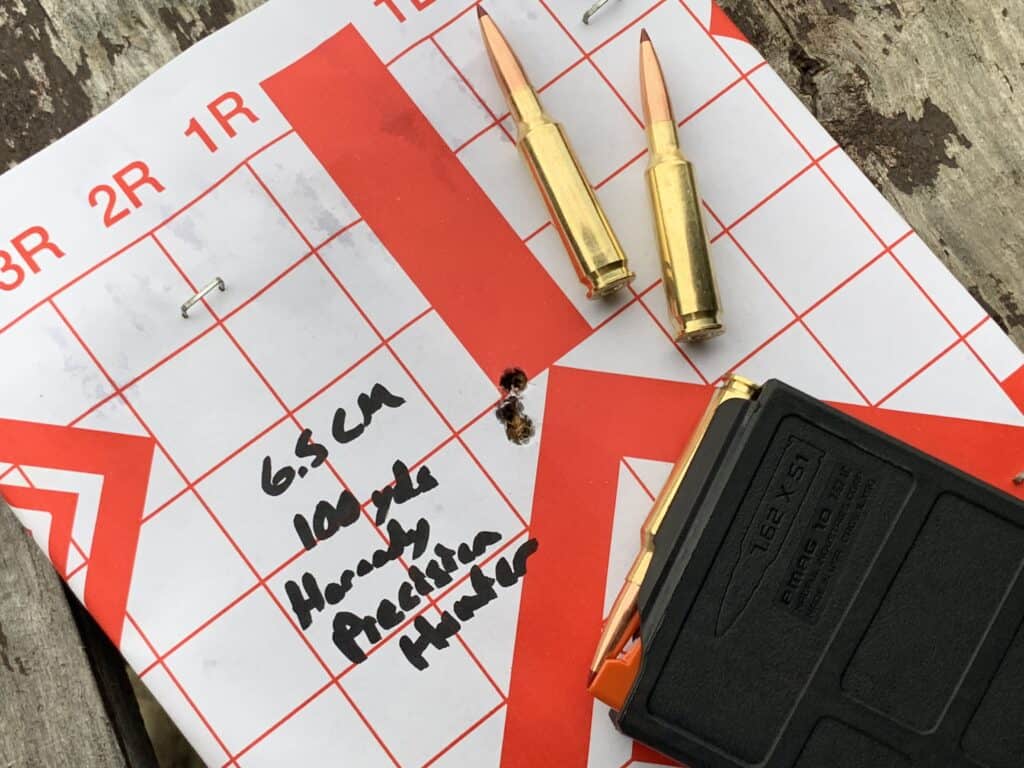

The SIG Cross has shot nothing but lights out for me, routinely shooting groups under 1/2″ with Hornady factory ammo. This accuracy is excellent for a factory rifle out of the box. I’ve read reviews about the Cross being picky with ammo selection so I may have just hit it right the first time with the Precision Hunter loads. I have started to develop hand loads for the rifle but haven’t gotten far enough along in the process to write about it at this time.

One thing that anyone looking at a Cross has to consider is the loss of velocity due to the shorter-barreled versions of the rifle. My example is in 6.5 Creedmoor with an 18″ barrel, and the Labradar clocked it at a slow 2,570 fps at the muzzle using 143-grain ELD-X bullets. This is pretty anemic for the 6.5 Creedmoor and is something the hunter needs to keep in mind when selecting a bullet for the rifle.

If you are interested in reading more about bullet selection, check out my article Your Bullet Choice is More Important than Caliber.

Rust, Rust, Rust…

At the long-range shooting course, it ended up raining almost the entire time. That moisture combined with the 90+ degree temperatures made for a very humid environment. Like others who have reviewed this rifle before me, I need to comment on the lack of corrosion resistance that the Cross’s Stainless steel barrel offers. It immediately began to rust.

I know what you are thinking, just oil it. You are correct. However, here lies one of the faults of the design in my opinion. You have to remove the handguard to access the barrel. Removing the handguard involves removing your scope rail and optic. So every time you want to oil the barrel you need to remove the optic and lose your zero. I’m sure there is something I can make that allows me to slide an oily rag underneath the handguard occasionally, but this all could have been prevented by applying a Cerakote finish to it, which I may do in the future.

Aside from that minor complaint, I am still very impressed with the rifle and am continuing to run it through its paces. I have mounted a DeadAir Sandman-S suppressor to it and have found it to shoot excellently suppressed as well.

Now, let’s dig in deep.

Technical Analysis: For the Nerds

The SIG Cross Action

When SIG introduced the Cross, it came as a surprise to most people. For a company that seemingly wins every Govt’ contract known to man, from pistols to machine guns, jumping back into the bolt action rifle market seemed out of their wheelhouse. What surprised me more than anything else though, is that it is so unique and not just another Remington 700 clone. In fact, it is about as far away from a 700-action as one can get!

For me, it is exciting to see this innovation. This is a result of thinking outside the box. Taking engineers used to designing much more complex designs such as belt-fed machine guns, and applying their brains to something much simpler, a bolt action.

While I may have already beat the uniqueness of the SIG Cross action to death, let’s take a look at the components that make up the action.

The Receiver

The one-piece receiver is made out of cast aluminum and sports an anodized finish. The barrel, trigger assembly, safety, bolt stop, buttstock, handguard, and Picatinny rail all attach to it. It is the heart of the design and what makes it so unique.

The channel that the bolt rides in is smooth and supports the bolt throughout all of its travel during operation. The channel is extended onto the buttstock as well, resulting in minimal bolt play when it is in the rearmost position.

The front is threaded for the barrel nut that secures the barrel extension to the receiver. This barrel nut is removed using an AR-15 disassembly wrench. The handguard also attaches to this part of the receiver using six screws.

The Bolt

The bolt on the SIG Cross has a 60-degree throw making it quick to reload. It is surprisingly easy to open after firing, and this is due to the rollers used on the cocking piece. As you open the bolt, the roller rides on the camming surface. As it reaches the final few degrees of lift, the bolt body cams against the barrel extension using mechanical advantage to pull the casing out of the chamber. This is your primary extraction.

Traditionally, the bolt handle provides this primary extraction. However, on the Cross, the receiver is aluminum, and using a steel bolt handle would wear on it quickly. So their use of the bolt body camming against the barrel extension is a great way to handle this issue.

1. Primary Extraction. Primary extraction occurs simultaneously with unlocking. The rim of the cartridge case is gripped by the extractor. During the final upward rotation of the bolt handle, the primary extraction cam partially retracts the bolt assembly completing the primary function of extraction.

2. Secondary Extraction. The bolt lugs are now free of the lugs in the barrel extension and the bolt can now be pulled to the rear, completing the secondary function of extraction.

As you pull the bolt to the rear, the spring-loaded plunger will launch the brass casing clear of the ejection port. As the bolt reaches the rear, it stops solidly on the bolt stop. In the rearward position, the bolt has minimal play. This is due to the design of the receiver. It has a channel milled into it that hugs the bolt throughout its travel. It feels a little gritty at first, but with a little lubrication and a few boxes of shells through it, it becomes very smooth to operate.

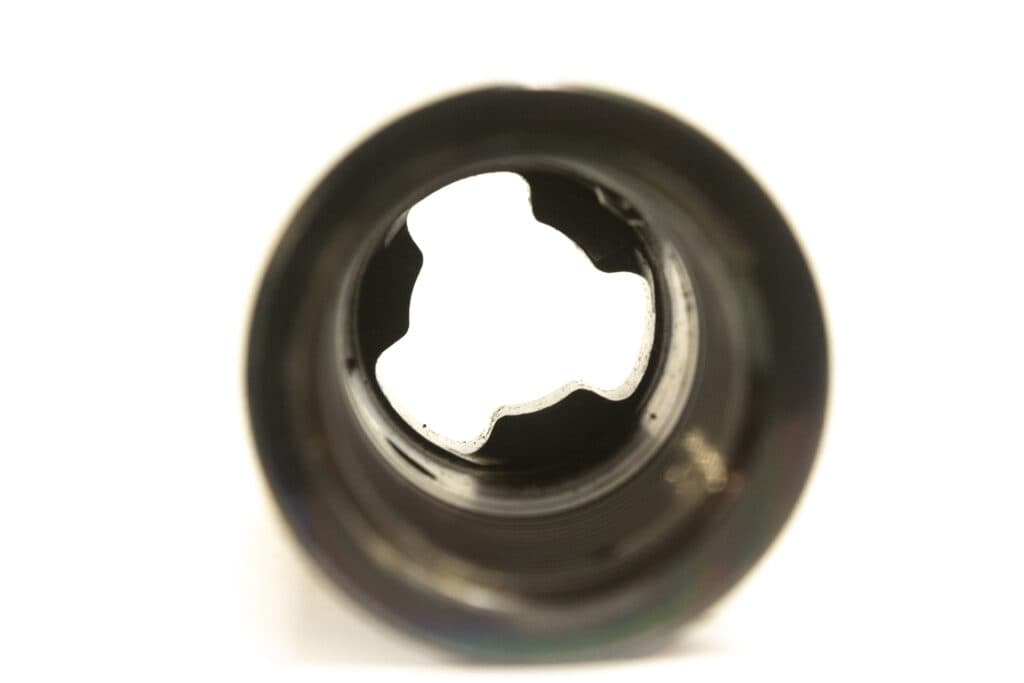

The Bolt Head

The Cross bolt also utilizes a bolt head that is removable. While there isn’t anything on the market at the moment that supports larger or smaller case diameters, it would be easy to adapt to this later. The bolt head is also unique because it doesn’t have 90-degree shoulders like the traditional bolt action. The bolt lugs are cut at approximately 60 degrees and create an angled locking surface. This increases the surface area and in theory, creates a stronger design.

Recently, SIG released what they call a +P bolt head assembly. It is a factory replacement part and is capable of handling +P cartridges. “+P” cartridges are ones that are higher pressure than normal SAAMI spec. This is interesting, as it is a sign that they may have had trouble with the bolt head strength recently. A strong bolt head will be absolutely necessary when all 80,000 PSI of the .277 Fury is released.

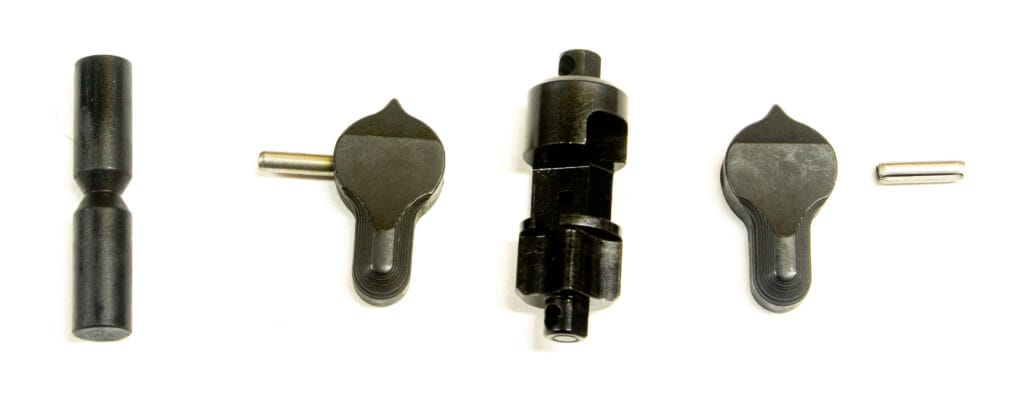

The bolt head contains both the extractor and ejector assemblies.

Extractor

The extractor is a non-rotary hook style that is keyed into the bolt head and held in place by a spring and ball bearing. The extractor itself is made of a flat piece of steel and very strong. This is a tried and true design that was patented by none other than Paul Mauser way back in 1890(U.S. Patent 431,669). This design was also found on Post-64 Winchester Model 70s as well as the Winchester Model 88 and 100 rifles.

Ejector

As mentioned previously, the ejector is a spring-loaded plunger held in place by a roll pin. On the magnum version of the Cross, there are two ejectors in the bolt head. This style ejector is used on just about everything now and is hard to beat for nice positive ejection.

EJECTION The spring-loaded ejector applies constant pressure to the left side of the cartridge head. As the bolt is pulled to the rear, the front edge of the cartridge reaches the ejection port on the right side of the receiver. Pressure exerted by the ejectors, and the pulling effect of the extractor on the right side of the cartridge case head, causes the cartridge to be rotated and ejected out through the port.

The Bolt Stop

The bolt stop assembly comprises four parts and is housed in the receiver underneath the Picatinny rail. The plunger protrudes through the top of the receiver and rides in a milled-out channel in the bolt body, serving as an additional bolt guide until the bolt reaches its rearmost movement. Care must be taken when removing the scope rail as the bolt stop spring can easily be lost.

The SIG Cross Trigger Mechanism

Much like everything else on this gun, the trigger mechanism is completely unique. First and foremost, when removed from the receiver, you will notice that the whole mechanism is housed in a skeletonized aluminum housing. It is held in the receiver with a detented cross pin, bolt, and safety assembly. This housing holds all of the trigger components, as well as the mag release. Additionally, the housing acts as the trigger guard and mounting point for an AR-15 grip of your choice.

The trigger itself is a two-stage design that is adjustable between 2.5 and 4 pounds using a single T15 screw accessed through the trigger guard. Turning the trigger adjustment screw counterclockwise will decrease the weight of pull, lightening it and vice versa. This adjustment affects both stages of the trigger pull simultaneously. Therefore, you can’t adjust each stage on its own. Over-travel and creep are not adjustable by the user.

Use coupon code KTG10 to get 10% off your order of $150 or more at Brownells.

Pressing the trigger rearward rotates the trigger bar and a series of levers that release the sear. The sear is cammed down by pressure from the main spring-loaded striker assembly. The striker assembly is driven forward under spring force to strike the primer of the cartridge loaded in the chamber, firing the cartridge.

I will dive deeper into the trigger assembly at a later date.

The Safety

The safety mechanism on the SIG Cross has two positions; safe and fire. When safe is selected, movement of the sear is blocked by the selector body. The bolt is able to be opened and closed while the rifle is on safe and is not locked.

The Cross’s safety has been one of the few major complaints with the design. It is an AR-style safety that rotates 90 degrees to engage and is fully ambidextrous. The complaints stem from the fact that it seemingly has a detent about 60 degrees into the rotation, giving you a false sense that it is fully engaged. While the rifle will not go off when in this 60-degree position, it is still something to keep in mind while using it. I pulled the safety out, added a dab of grease to detent surfaces, and that smoothed it up considerably.

It is also worth noting here that SIG had a safety recall on their early Cross rifles. A lot has been written about it so I won’t cover it here. However, this article by American Rifleman covers its extent. You can check your serial number for the recall here.

The Picatinny Rail

The Picatinny rail is attached to the receiver and handguard by four T-25 screws torqued down to 35 in-lbs. This top rail holds the bolt catch spring in place, and care must be taken when it is removed. For the Cross and Cross-PRS models, the rail is a 0 MOA rail meaning that there is no angle built into it for distance shooting. The Cross STX model’s rail is a 20 MOA rail. SIG sells an aftermarket 20 MOA rail for those looking to modify their 0 MOA rails.

The Barrel

The barrel weight and length on the SIG Cross varies from model to model; therefore, we are only going to talk about the design itself as it is one of the unique features of the cross design. It utilizes a Savage-style barrel nut in conjunction with a barrel extension. This serves two purposes. First and most importantly, headspace can be adjusted by the user to their liking. Secondly, it is relatively easy to swap barrels between calibers in a shop at home.

If you don’t quite understand what I mean by headspace or just want a better understanding of it, check out the article I wrote titled “Everything You Need to Know About Headspace.”

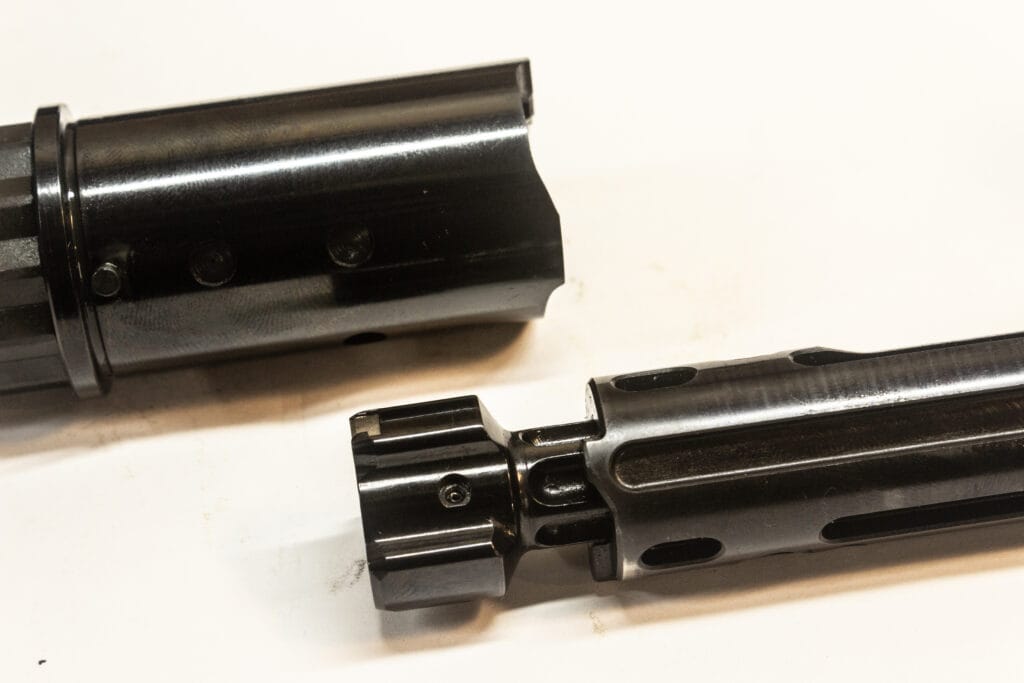

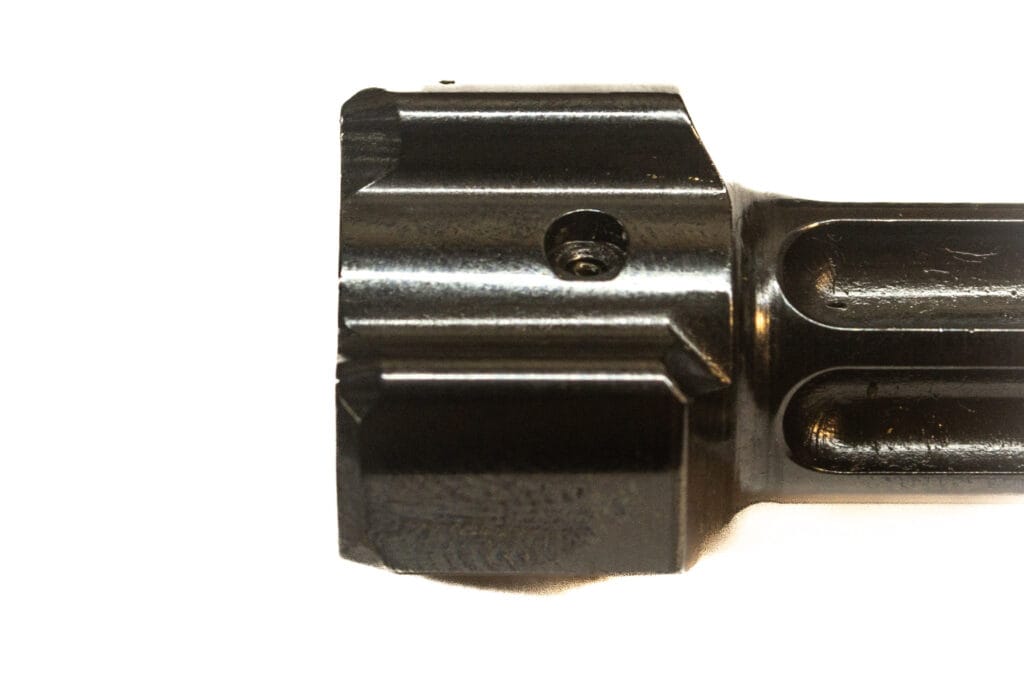

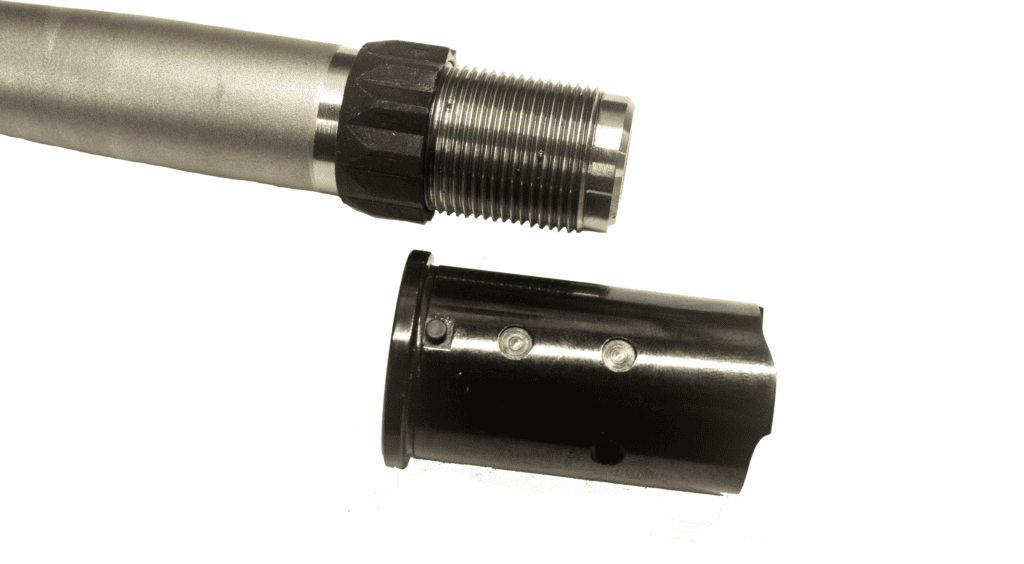

SIG Cross Barrel Extension

The barrel extension is the heart of this design. It serves multiple functions that are essential to a well-designed bolt action. The barrel extension is the primary reason that the SIG Cross can get away with using an aluminum receiver. It is threaded to receive the barrel and provides the locking strength needed during firing.

The barrel extension houses the locking surfaces with which the bolt head mates during the firing process. Since this is a tri-lug design, there are three corresponding locking surfaces, all varying slightly in dimension, further preventing the rifle from being assembled wrong.

Additionally, the barrel extension plays a major role in the primary extraction of the cartridge. There are two angled surfaces on the face of it that the bolt body rotates on during primary extraction. These camming surfaces make it easy to extract casings smoothly without hiccups.

Last but not least, the barrel extension has an indexing pin that ensures it is properly aligned with the receiver when installed.

Furniture: Stock, Grip, & Handguard

The primary goal of this article was to discuss the SIG Cross action itself. Up to this point I think we have covered that sufficiently, but I will briefly touch on the furniture of the Cross.

Buttstock

The buttstock assembly is adjustable for the length of pull, buttpad cant, buttpad height, comb height, and comb profile. On all models, excluding the PRS, the assembly is made of aluminum. The PRS model utilizes steel to add weight. The bottom of the stock has two threaded holes for use with a bag rider attachment.

The stock can be folded to the right side and when folded, locks closed, securing the bolt handle in the closed position. The folding mechanism is challenging to use at first, but once you are familiar with it, it is easy to operate. It is strong and provides a solid and stable buttstock.

Adjusting the stock to fit the shooter is easy and can be accomplished without the help of others. The buttpad cant and comb profile do require the use of some basic tools.

Pistol Grip

The pistol grip mounts to the trigger assembly and is compatible with all AR-15 pistol grips giving you unlimited options.

Handguard Assembly

The free-floating handguard is made of aluminum and has M-Lok attachment points the entire length of it. Depending on the model, a Picatinny rail extends down the length of the top rail. It mounts to the receiver using six screws and the scope rail mounts directly to the handguard as well.

Ultimately, this handguard is very rigid and doesn’t have any flex. Length, weight, and configuration vary by model.

SIG Cross Magazine Compatibility

The SIG Cross is designed to accept standard Accuracy International Chassis Magazine Short Action(AICS SA) mags, which are available pretty much everywhere. They can be found made of both polymer and metal, giving the user many options. The Cross comes with either a 5 or 10-round Magpul mag, depending on the model purchased.

This is where things get a little interesting with the magazines. You’ll quickly notice that Magpul makes both a standard AICS mag and one designed specifically for the Cross rifle. The difference lies in the follower used in the magazine. The Cross-specific magazine utilizes a follower that has a raised portion in the front that acts as a “load” or feed ramp for the last cartridge in the magazine.

Using both the 5 and 10-round Cross mags, I was happy to have very smooth feeding through the 200 or so rounds I’ve put through the gun so far. As for the Magpul standard AICS magazine(without the Cross follower), the guys over at Rifle Shooter Magazine had trouble. “With this magazine, the Cross’s bolt didn’t pick up a fresh cartridge 40 percent of the time when the bolt was cycled.” They did add that a 10-round mag made by Accurate Mag functioned perfectly.

While there are some small nuances with the magazine compatibility, if you buy the right magazines, you will not have a problem. For those of you who already have a stock of standard Magpul AICS mags, I completely understand your frustrations. Maybe they will someday offer follower upgrades for you.

SIG Cross Models Explained

| Model | Calibers | Barrel Length | Weight | Other Features |

| Cross | 6.5 Creedmoor, 308 Winchester | .308 – 16″, 6.5 – 18″ | 6.8 lbs | Most Affordable |

| STX | 6.5 Creedmoor, 308 Winchester | 20″ | 7.7 lbs | 20 MOA Top Rail |

| PRS | 6.5 Creedmoor, 308 Winchester | 24″ | 14.2 lbs | ARCA Rail |

| Magnum | 300 Win Mag | 24″ | 8.9 lbs | 5R Rifled |

Cross Rifle – $1599.99

This is the original SIG Cross that was designed for the purpose of hunting. It is the shortest and lightest model Cross at the moment. This is the model that I examined throughout this article. It is also available with a camo finish for an additional $200.

Cross STX – $1999.99

The STX model of the SIG Cross is plain sexy. Sporting a 20-inch heavy barrel and full-length 20 MOA top rail, it can accept any optics combination you can dream up. The stainless steel barrel has a corrosion-resistant finish and is equipped with an SLH/SLX suppressor-ready QD flash hider. A few other upgrades over the base model include a paddle mag release and thumb rest safety.

Cross PRS – $2499.99

The SIG Cross PRS is reconfigured with the competitive shooter in mind. Much of the aluminum, including the stock, has been replaced by steel on this model, adding weight to help with quicker follow-up shots. Weighing in at 14.2 lbs this rifle is beefy, to say the least. It sports a Cerakote finish and heavy contoured stainless 5R rifled barrel. The two-piece handguard includes an ARCA rail for direct mounting to tripods.

The Magnum Action – $2499.99

At the time of this writing, SIG quietly released their Cross Magnum rifle. Chambered in the 300 Win Mag, it is exactly as it sounds, a magnum-sized Cross action. The receiver length is capable of handling cartridges such as the 300 PRC as well. The rifle feeds from magnum-sized AICS magazines, meaning there are many options on that front.

Aside from the length of the receiver and bolt components, there are a few differences between the magnum and standard length action. First and foremost is the dual ejectors found on this model. This is undoubtedly there to help throw the heavy magnum brass clear of the ejection port without any issues. Additionally, the stock hinge has been changed and beefed up slightly.

Tools Needed to Maintain & Work On Your SIG Cross

Ultimately, the SIG Cross is very easy to maintain at home with a few basic tools. Below is a list of tools I recommend that will allow you to perform any maintenance procedure you might want.

- T15 Drive Bit

- T25 Drive Bit

- T30 Drive Bit

- Torque Wrench

- 1/16″ Roll Pin Punch

If you are planning on swapping barrels, these additional tools will help you accomplish that task.

- 1 1/16″ 16-point box end wrench

- Barrel Vise

- AR Disassembly wrench

- Go/No-Go Gauges

SIG Cross Torque Specs

| Part | Torque |

| Barrel Nut | 40 ft-lbs |

| Barrel Jam Nut* | 50 ft-lbs* |

| Bolt Knob | 40 in-lbs + 263 Red Loctite |

| Buttpad Cant Screws | 12.5 in-lbs |

| Handguard Screws | 17 in-lbs + 222MS Purple Loctite |

| Length of Pull Knob | Hand Tighten Only |

| Quick Detach Sling Mount | 35 in-lbs |

| Stock Hinge Screws | 50 in-lbs |

| Top Rail Screws | 35 in-lbs + 243 Blue Loctite |

Closing Thoughts on the SIG Cross

I truly believe that the SIG Cross is a step forward in the evolution of the bolt action rifle. While it got some bad press early on due to the safety recalls, it has proved to be a very capable platform. If you have any experience with the Cross let me know in the comments below, I’d like to hear the good and bad you’ve experienced! This article will be ever-evolving as I continue to use this rifle. If there is something else that you think I should add, shoot me an email and check back for updates!

Written by: Kurt Martonik

Kurt is a Gunsmith, Reloader, Hunter, and Outdoorsman. He grew up in Elk County, Pennsylvania, where he became obsessed with the world of firearms. Following high school, Kurt enlisted in the United States Air Force as a Boom Operator, where he eventually rose to the position of Instructor. After his military service, he attended the Colorado School of Trades(CST) in Lakewood, CO for gunsmithing. Following graduation, he accepted a job at C. Sharps Arms in Montana, where he worked as a full time stockmaker and gunsmith.

Same objection I have to AR10 big game rifles, they just are uncomfortable to carry for any length of time. Even AR15 HBARs are not any thing I want to pack around hunting. Then the aesthetics, if hunting is seen as a utilitarian activity, then this is going to satisfy. But like most people who pursue fly fishing or upland bird hunting, I go into the field for the overall experience and carrying a nice sporting rifle contributes to the overall experience. To each his own though, and your assessment of it being the future of off the rack firearms may be correct. They certainly aren’t going to require a skilled gunsmith to work on. Basic armorer skills will suffice, so long as a guy can read a technical manual and follow instructions they will be capable of switching out parts on them. There is a lot of profit to be had in something like this. They are not going to require much skilled labor in production either.

JD I couldn’t agree more with you. There is nothing like carrying a custom walnut-stocked rifle in the woods. I’m taking this rifle to Montana this year and it feels dirty, too easy honestly. But, freezer is full and I want to be selective this year in getting a mature buck, sometimes that means shooting further than my Mauser likes to. I will do it this one time then be back to the wood stocks. The experience with a nice sporting rifle is unmatched.

As for this being the future of bolt actions, that’s the way it is headed. I’m at a crossroads because I value tradition more than anything, but I also like to see advancements in technology applied to these simple machines we call rifles.

I’ll be missing my G33/40 when the temps drop this November and I have to grab that lifeless aluminum receiver…

I used to visit the rifle shops in and around the Livingston when my grandfather was still alive and although I never bought a rifle made in Big T, or as we used to call it, Big Limber Banana, it was a blessing just to have the opportunity to watch the skilled work going on. I really am one to talk about utilitarian, I took my beautiful CZ 527 American in 17 Hornet apart last year and put a varmint weight barrel on it and put it in an HS Precision Kevlar stock that has an aluminum bedding block. Yes, it’s slightly more accurate and is a sub half minute rifle now and I have walnut stocked 527 Americans in 22 Hornet and 204 Ruger that are just as accurate as the Kevlar stocked 17 so there is that. There are times when I’m out for blood that I grab my McMillan stocked Model 70 Winlite in 300 WBY and when we are bench shooting varmints my bolt action rifles are all in either MPI or HS Precision stocks, but more often than not if I’m out for the experience I’m going to be taking an Model 71 or 86 in 45/70 big game hunting or a Model 43 Winchester walking around varmint shooting. It isn’t that I have a fundamental objection to utilitarian rifles, it is more of a frustration with them displacing rifles that have style and class in the marketplace.

We have been using AR15 rifles for decades and one thing for sure and for certain, they can be easily configured to fit kids and that has made them a good option to let the kids reach out past where their 17 Hornet Contender carbines leave off for bench shooting rockchucks and prairie dogs. I can totally comprehend the value in someone who doesn’t have the skills or tooling to custom fit stocks on a Contender or Encore or any rifle rifle for that matter having something available that can be fitted to practically any shooter. I went with the TC single shots because we have a lefty, and butt stocks that could be cut down were a dime a dozen. My oldest daughter has her Encore in 243 that is stocked to fit her and she has an AR in 223 and the AR is more accurate, but my inclination is that she is partial to the Encore. The Encore is good for a minute of angle and the AR abut half that. If you missed out to 500 yards or so, it wasn’t the gun.