Understanding the headspace of a firearm can be tricky and hard to grasp. It is an important measurement that verifies whether a gun is safe to shoot.

Headspace is the measurement that standardizes cartridge dimensions for both ammunition and firearms manufacturers. It is one of the most important measurements found on a firearm and is essential for safety and functionality. Headspace also plays a major part in the accuracy of the gun itself.

Let’s take a look at headspace, why it’s important, and how to measure it.

Affiliate Disclosure: This article may contain affiliate links. When you use these links, I earn a small commission from each sale generated at no cost to you. This commission helps me continue to put out free content. I work a full-time job that I am very happy with; therefore, I don’t need this commission and am not obligated to speak highly of any product. Everything written is my own opinion: the good, the bad, and the ugly.

Table of Contents

What is Headspace?

Headspace is the distance between the rear and forward stopping point of the cartridge. The breech face is the rear stopping point of the cartridge, while the forward stopping point varies by the type of cartridge.

The Five Types of Cartridges

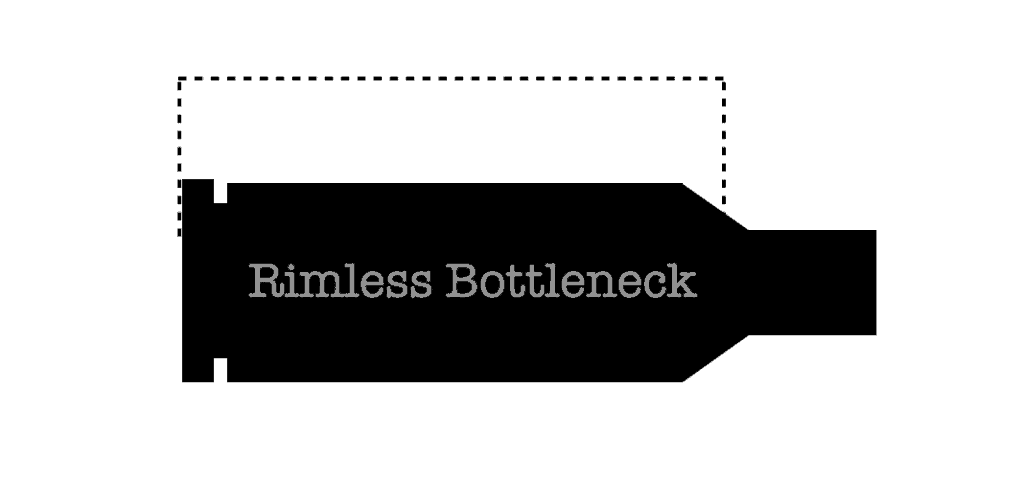

Rimless Bottleneck – Cartridges with a bottleneck, such as the classic 30-06 without a rim or belt. These are measured from the rear of the cartridge to its datum line. The datum line is determined by SAAMI but typically falls halfway down the shoulder of the cartridge.

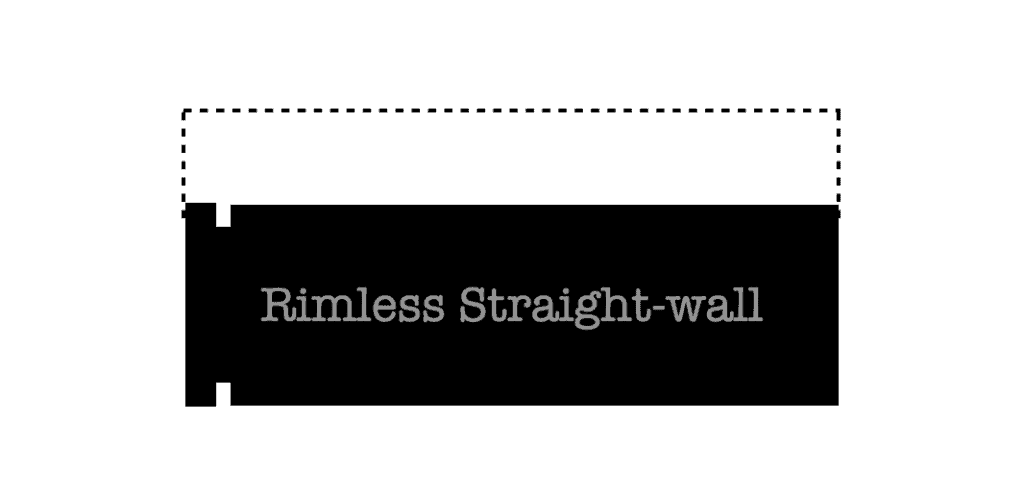

Rimless Straight-Wall – Straight-wall cartridges without a rim, like the 45 ACP or .30 Carbine. Measurement is taken from the rear of the cartridge to its mouth. An excessive crimp on a cartridge like this can change the headspace.

Rimmed – A cartridge with a rim larger than the cartridge’s body, like the 30-30 Winchester and 303 British. The headspace measurement is from the rear of the cartridge to the front of the cartridge rim.

Belted Magnum – A cartridge with a belt around the base, such as a 300 Win Mag. The headspace is measured from the rear of the cartridge to the front of the belt.

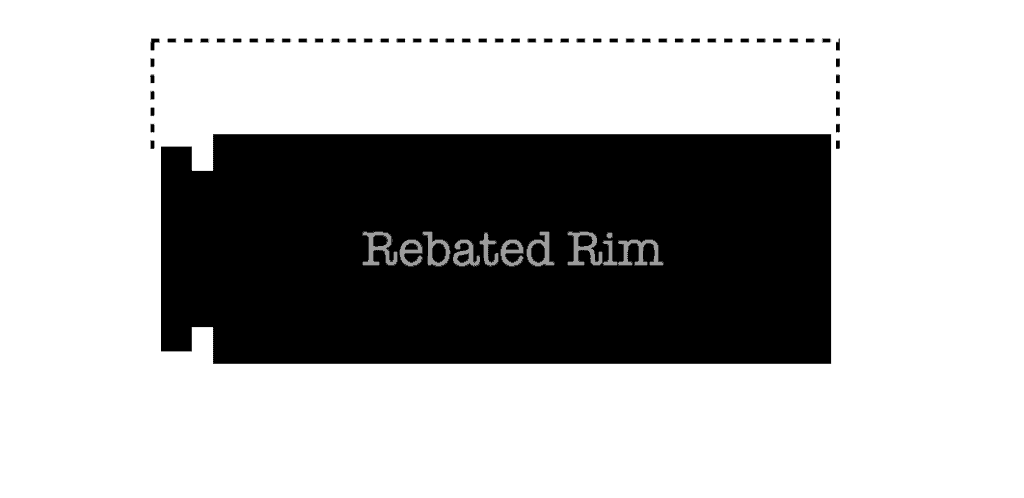

Rebated Rim – A cartridge where the rim is a smaller diameter than the body of the cartridge, such as the 50 AE and 50 Beowulf. The measurement is the same as a rimless straight-wall and is taken from the rear of the cartridge to its mouth. If the rebated rim is on a bottleneck cartridge, the headspace is measured off of the datum line.

Why Headspace is Important

The term headspace refers to three measurements related to each other; the dimension of the cartridge itself, the dimension of the firearm’s chamber, and the “space” or difference between the two. Headspace standardizes cartridge dimensions for both ammunition and firearms manufacturers.

As a cartridge is fired, the primer is struck, igniting the powder charge. The burning powder creates an enormous amount of pressure that expands the brass to create a seal in the chamber and drive the bullet down the bore of the barrel. The brass expands to fit the internal dimensions of the chamber and stretches against the breech face.

A firearm with excess headspace may have too much of a gap for the brass to expand and fill. This potentially causes the brass to stretch until a point of failure, letting hot gases escape the chamber area.

SAAMI(Sporting Arms and Ammunition Manufacturers Institute, Inc.) sets the guidelines for what dimensions will allow a firearm to operate safely. When headspace is checked by a gunsmith, it is checked on the firearm itself. This is due to the chamber remaining constant throughout its life. Ammunition plays a big role in the headspace, but with so many different manufacturers and types of ammo, it is nearly impossible to get an accurate reading of headspace on the ammunition alone.

Ammunition Dimensions are Critical

It is important to understand that no factory cartridges are absolutely uniform, even with today’s technology. Just like in chambers, there are minimum and maximum dimensions for ammunition as well. Ammunition is to be made within these specs so that it will operate safely in any firearm that is properly chambered and headspaced.

A properly headspaced gun means nothing if the ammunition is out of spec. However, as previously noted, we rely on the manufacturer to make ammunition to SAAMI spec. While we do the same with rifles, it is much more likely that a rifle or handgun will need its headspace measured by a gunsmith. So we are going to focus on how headspace is measured for firearms, not ammunition.

How It’s Measured

Headspace is measured using a set of precision ground gauges. The gun is disassembled so that nothing interferes with the insertion of the gauges. Extractors, ejectors, and anything else under spring pressure must be removed to get an accurate measurement. There are two(sometimes three) gauges that are needed to measure headspace; they are outlined below.

Go & No-Go Gauges Explained

Headspace gauges are needed to check headspace properly. These gauges are precision machined and inserted into the firearm’s chamber. Their dimensions are outlined by SAAMI, with the exception being wildcat cartridges that may require their own special gauges. It is also important to note that these gauges only measure headspace and do not measure every aspect of the chamber. Three types of gauges are found; Go, No-Go, and Field.

The “Go” gauge represents the minimum chamber dimensions for that specific cartridge.

A “No-Go” gauge is made to the maximum headspace dimension recommended for new rifles.

The “Field” gauge is the longest of the three gauges and is slightly below SAAMI maximum. These gauges are typically only used with NATO cartridges and the arms associated with them.

Care must be taken when handling headspace gauges as they are precision ground and hardened, making them easily damaged if dropped.

Use coupon code KTG10 to get 10% off your order of $150 or more at Brownells.

Headspace Gauge Interchangeability Chart

Headspace gauges are expensive. Fortunately, you don’t need a headspace gauge for every caliber known to man. In fact, many of them are interchangeable. For example, the 270 Winchester is essentially a necked-down 30-06. Because of this, 30-06 headspace gauges are used to headspace 270 Rifles. Below is a chart outlining which gauges work for which calibers.

| Headspace Gauge | Compatable with these calibers |

| .22 Dasher | .20 Dasher, .30 Dasher, 6mm Dasher, 7mm Dasher |

| .22 Short/Long/Long Rifle | .17 Mach II, .17 RF Aguila, .17 PMC, .17 High Standard, .22 Bentz, .22LR Match, .22 Lilja Match, .22 RF, .22 Freeland Magnum |

| .22 WMR | .14 RF Mag, .17 HMR, .17 RF Match, .22 WRF Short Body, .22 WRF |

| .22 Hornet | .17 Hornet, .17 K-Hornet, .20 K-Hornet, .22 K-Hornet, All other .22 Hornet based wildcats |

| .22-250 | .20-250, 6mm-250 |

| .222 Remington Mag | 6×47 Remington |

| .223 Remington | .17/223, .17 Practical, .20 Practical, .223 Wylde, .25-45 Sharps |

| .32-20 WCF | .218 Bee, .218 Mashburn Bee, .25-20 WCF, 17 Ackley Bee, .17 HeeBee |

| .26 Nosler | .28 Nosler |

| .284 Winchester | 6mm-284 Win, 6.5mm-284 Win, .22-284 Win, .25-284 Win, .30-284 Win, .35-284 Win, .270-284 Win, .338-284 Win, .284 Shehane, .284 Lapua, .284 Norma |

| .300 RSAUM | .25-300 RSAUM, .270-300 RSAUM, .338-300 RSAUM, 6mm-300 RSAUM, 6.5mm-300 RSAUM, 7mm RSAUM, 6.5 GAP (GA Precision) |

| .300 RUM | .338 Edge, .270 RUM, .358 RUM, .375 RUM, .458 RUM, 7mm RUM |

| .300 WSM | .270 WSM, .325 WSM |

| .30-06 Springfield | 6.5mm-06, 6.5mm-06 A-Square, .22-06, .223-06, .25-06 Remington, .243-06, 6mm-06, .270-06, .270 Winchester, .303-06, .338-06, .338-06 A-Square, 7mm-06, .35 Whelen, .375 Whelen, 8mm-06, .400 Whelen |

| .30-30 WCF (Winchester Center Fire) | .303 Savage, .219 Zipper, .219 Zipper Imp, .219 Donaldson Wasp, .25-35 WCF, .32-40 WCF, .30-30 WCF (CIP),.38-55 WCF (CIP), .30 Herrett, .32 Wincester Special, .356 Winchester, .357 Herrett, .375 Winchester, .375 Super Mag, .307 Winchester, 6mm-30×30, 7mm Waters, 7mm-30 Waters (CIP), 7mm International R |

| .30-40 Krag | .303 British, .40-70 Straight |

| .308 Winchester | .22-243 Win, .243 Win, .260 Rem, .270-08, .338 Federal, .338 Federal (CIP), .338-08, .338-.358 Win, .358 Win, 6.5mm Panther, 6.5mm-08, 7mm-08 Rem |

| .32 H&R Mag | .32 S&W, .32 Long Colt, .32 Colt |

| .338 Norma Mag | .300 Norma Mag |

| .357 Mag | .22 Rem Jet, .256 Win Mag, .357 Max, .38 S&W, .38 special |

| .378 Wby (Weatherby Large Belted Mag) | .30-378 Wby, .338-378 Wby, .416 Wby, .460 Wby |

| .44 Rem Magnum | .44 Special or .44 S&W Special, .45 Colt or .45 Long Colt, 454 Casual CIP, .445 Super Mag, .460 S&W Mag |

| .44-40 WCF | .38-40 WCF |

| .45-70 Government | .33 WCF, .348 Win, .50-90 Sharps (.50×2-1/2″) .40-65 WCF, .40-82 Win, .45 Basic, .45-60 Win, .45-90 Sharps (.45×2-4/10″), .45-110 (.45x 2-7/8″), .45-120 (.45x 3-1/4″), .450 Alaskan, .50 Alaskan, .50-70 Government, .50-110 WCF, .50-140 Sharps (50x 3-1/4″ |

| 5.56×45 NATO | The cartridge is proprietary and NOT interchangeable with .223 Rem |

| 6.5mm Creedmoor | 6mm Creedmoor, 7mm Creedmoor, .30 Creedmoor, .338 Creedmoor |

| 7x57mm Mauser | 257 Roberts, 6.5-257 Roberts (CIP NOT COMPATIBLE!) |

| Std belted Mag (Standard Belted Magnum) .535 Base | .257 Wby, .264 Win Mag, .270 Wby Mag, .275 H&H, .300 H&H, .300 Wby Mag, .300 Win Mag, .308 Norma Mag, .338 Wby Mag, .338 Win Mag, .340 Wby Mag, .350 Rem Mag, .358 Norma Mag, .375 H&H, .375 Wby Mag, .375 STW, .400 H&H, .416 Rem Mag, .458 Lott, .458 Win Mag, 7mm Rem Mag, 7mm STW, 8mm Rem Mag |

How to Check Headspace

- To check headspace, start by disassembling the gun so that nothing interferes with the bolt or slide closing on the gauges. That means you need to remove extractors, bolt-mounted ejectors, and even the firing pin assembly.

- Insert the Go gauge and slowly close the bolt or slide. The bolt should rotate into full battery without any resistance.

- Carefully remove the Go gauge and set it aside.

- Insert the No-Go gauge and slowly close the bolt. Never force a bolt closed! You should feel some resistance or even a hard stop before it closes into full battery. If it closes without resistance on the No-Go gauge, you need to take your gun to a gunsmith.

When to Check Headspace

Headspace should be checked anytime barrel or bolt work is performed and when buying a used firearm. Action work, lapping lugs, and rebarrels are all times when you may need to check headspace again. A gunsmith will automatically check the headspace of the guns that he is performing this type of work on. You should also have it checked when buying used firearms, as you don’t know if the headspace is still good.

Indicators of Excess Headspace

Fortunately, a few indicators let us know that a firearm may be approaching excess headspace.

- Light Primer Strikes

- Failure to Fire

- Bulged or Blown Cases

- Unseated Primers after firing

- Case Failures

- Cracked case necks

- Case head separation

These indicators could also mean a number of other things, so having a professional look at the gun is the best idea. If you are looking for a gunsmith and need help finding one, check out the article I wrote below.

Article: How To Find the Right Gunsmith

Signs of Insufficient Headspace

The signs of a gun having insufficient headspace are much more obvious than excess. If your rifle has insufficient headspace you are more than likely going to experience a failure to go into battery. The bolt won’t fully close. This can also be seen as having a tight chamber. The good news is that you shouldn’t ever run into this problem with an existing gun. The only time you’ll potentially see it is on a new firearm which should be covered under warranty.

Correcting Excess Headspace

If your gun has excess headspace, it is not the end of the world. Excess headspace can be corrected in a number of ways. However, it is primarily done by “setting the barrel back.” That term is frequently used by gunsmiths to indicate that the thread end of the barrel will be shortened and the chamber recut. This is a timely process that involves timing the barrel right so that the sights or manufacturer stampings line up just right.

There are some other ways of accomplishing the same thing, but many people elect just to have a new barrel put on as the cost isn’t all that much more to do.

Does Headspace Effect Accuracy?

Headspace can play a part in the accuracy of a firearm. In particular, when it is tailored to one specific type of ammunition. This is very evident in rimfire designs and can really make any old 22 a tack driver. I go over in detail how adjusting the headspace on my CZ-457 made a huge difference in accuracy in this article, The Most Affordable Way to Accurize Your CZ-457.

Written by: Kurt Martonik

Kurt is a Gunsmith, Reloader, Hunter, and Outdoorsman. He grew up in Elk County, Pennsylvania, where he became obsessed with the world of firearms. Following high school, Kurt enlisted in the United States Air Force as a Boom Operator, where he eventually rose to the position of Instructor. After his military service, he attended the Colorado School of Trades(CST) in Lakewood, CO for gunsmithing. Following graduation, he accepted a job at C. Sharps Arms in Montana, where he worked as a full time stockmaker and gunsmith.

Hello. I always check headspace, except for just recently. I have a 50 bmg and accidently oversized my brass by .010″ to .050″ which is way to much. I was told to reload the brass with a very lite load of powder and the brass will reform to the chamber properly. I believe this will work, however, the case head will probably be thinner and over time will not work long.

What are your thoughts?

Jumps

Jumps,

If you oversized your brass, your best bet is to pull the bullets and run them through the full length sizer. I have never tried the light load of powder to do that so I can’t speak to that method. I will say that if you are going to try it be very careful. Light loads can cause excess pressure.

-Kurt

Can’t find any headspace gauges for my 50ae desert eagle. Any idea where I could find go and no go gauges?

Thanks

Guy,

Sorry for the late reply, check 4D reamer rentals, they have a large selection of go and no go gauges that you can rent. If you are looking to purchase them, give PTG(Pacific Tool & Gage) a call.

Jumps and Kurt,

I’ve done some research into fireforming a casing to a chamber. The procedure is online on several reputable sites. Search for cream of wheat (COW) fireforming. The light charge < ~15% of normal, some cream of wheat in the case to fill and hold the charge close to the primer and a little TP or wax to hold it in seem important to the process. Apparently, this is also referred to as a Shehane case when you're done.

I echo your comment for caution if you move forward with this.